Isishwankathelo se-electroplating

Kwishishini, sihlala siva malunga ne-metal electroplating okanye i-electroplating craft.kodwa ngaba uyazi nge-electroplating kunye nendlela yokuyisebenzisa ukuphucula iimveliso?Eli nqaku liza kwazisa ngokucacileyo ulwazi malunga ne-electroplating kuwe.

Kutheni ukhetha iteknoloji ye-abs electroplating

Kwelinye icala imveliso yeplastiki ye-electroplating inophawu lweplastiki kunye nentsimbi, kwangaxeshanye inomxhuzulane okhethekileyo, ukumelana nokugqwesa okulungileyo, ukubumba okulula, ukucwebezela kwesinyithi kunye nokuthungwa kwesinyithi, kunye nokuhamba kombane, ukufikeleleka kwemagnethi, kunye neempawu zokuwelda. .Ngokwalo msebenzi wobugcisa, unokugcina inkqubo enzima kwaye uphephe ukumosha isinyithi ezibizayo kwaye intle kwaye ihombise.Ekubeni intsimbi yentsimbi inozinzo oluphezulu kwizinto zangaphandle ezifana nokukhanya, umoya, njl., Emva kokuba iplastiki ifakwe ngesinyithi, inokwandisa ubomi benkonzo yemveliso yeplastiki.Ngophuhliso lweshishini, itekhnoloji ye-Electroplating isetyenziswa kakhulu kwiinkalo ezahlukeneyo, iye yaba sesona sixhobo sibalulekileyo sokuhombisa umphezulu kwiimveliso zeplastiki.Okwangoku, isetyenziswe ngokubanzi ukuhombisa umphezulu we-ABS, i-polypropylene, i-polycarbonate, i-polycarbonate, i-nylon, i-polystyrene, kunye nezinye iiplastiki.Phakathi kwabo, iplastiki ye-ABS yeyona nto isetyenziswa kakhulu kwi-electroplating kwaye isiphumo se-electroplating sesona silungileyo.

Ziziphi iingenelo ze-abs electroplating

Iplastiki ye-Abs ineempawu ezininzi zoshishino ezenza ukuba ibe yeyokuqala ukukhetha izinto ezisetyenziswa kwimizi-mveliso, kodwa isenesiphene samandla aphantsi kwaye ichatshazelwa lula ngamaqondo obushushu kwaye iphazamiseke ngokulula kwaye ingaqhubeki.Nangona kunjalo emva kwe-electroplating, iplastiki ye-abs iya kufumana iimpawu ezintsha ezinje:

1.Amandla

2.Ukuthembeka kwesakhiwo

3.Ukumelana nobushushu

4.Isibheno sobuhle

5.Ukumelana nokubola

I-6.Ukuqina kunye nokuxhathisa i-abrasion

I-Electroplating inokwenza nayiphi na iplastiki ye-abs ineempawu zetsimbi, kwangaxeshanye iingcali zinokususa idiphozithi yentsimbi ebambelelayo ekugqityweni kwekhemikhali ngaphandle kwe-abrasion yoomatshini, enokunciphisa ixesha kwinkqubo.

Ukusetyenziswa kwe-abs electroplating

Kutshanje, itekhnoloji ye-electroplating ihlala isetyenziswa ekwenzeni iinxalenye zeemoto.Ngenxa yeempawu ezizodwa zeplastiki ye-ABS, inokwenziwa kuyo nayiphi na imilo ngabayili, kunye netekhnoloji ye-electroplating iyenza ibe namandla aphezulu, ngenxa yoko sihlala sibona obu buchwepheshe busebenza ekwenzeni iimoto.Ezinje: iigrilles, iibezel ezikhanyayo, ii-emblem, amaqhosha okutshintsha izixhobo, izibambo zocango kunye neebhampa.

EZINYE IZICELO

Iimveliso ezikwaziyo ukumelana nobushushu: Iindawo zeplastiki ezivezwe kumaqondo obushushu aphezulu kakhulu ngexesha lokwenziwa okanye ukusetyenziswa kokuphela kokusetyenziswa kunokuba sesichengeni sokonakala kobushushu.Ingubo yentsimbi inokusebenza njengekhuselo le-thermal elinciphisa umngcipheko.

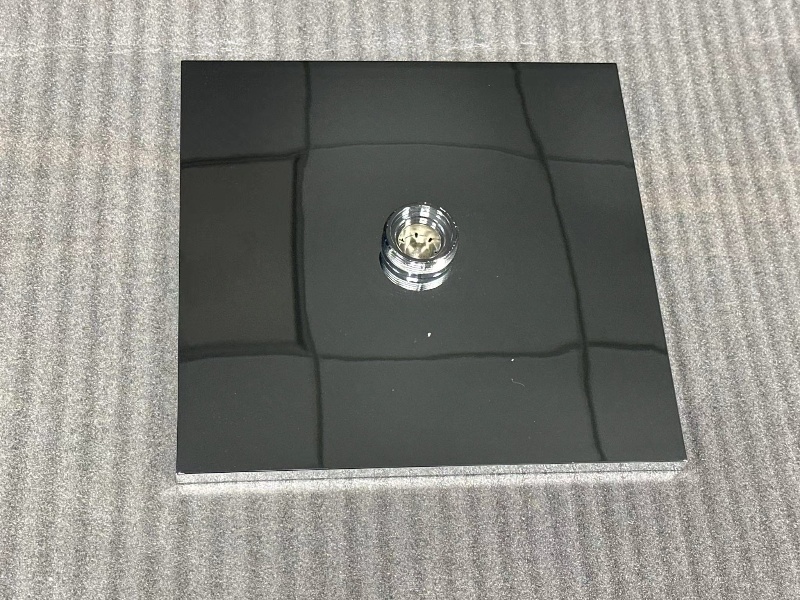

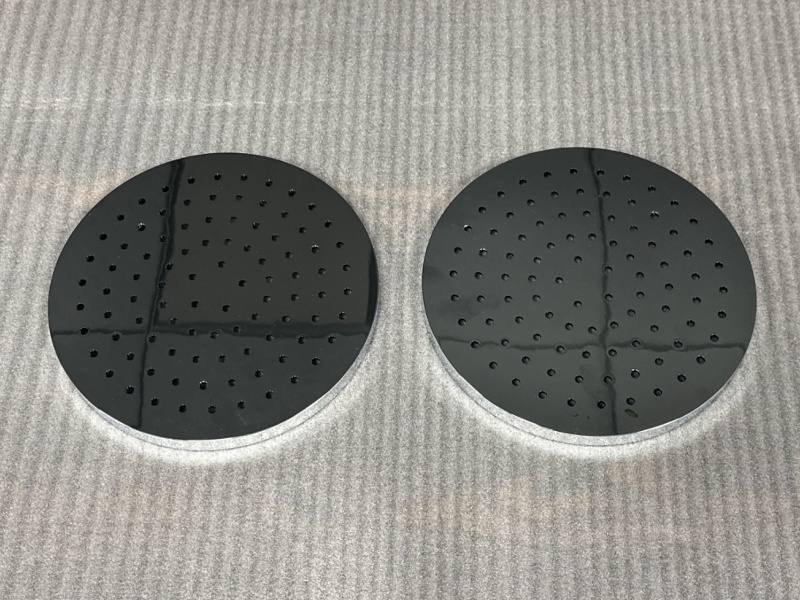

Iimveliso zegumbi lokuhlambela: Ukufakwa kwiiplastiki kwazisa iimpawu zococeko eziyimfuneko kwiimveliso ezifuna ukucoceka kunye nococeko - indawo yeplastiki enentsimbi ikhuthaza ukucoceka okulula, okusebenzayo.Imizekelo yeemveliso ezihambelana nesi sicelo ziquka izixhobo zeshawa, izincedisi zekhitshi kunye negumbi lokuhlambela kunye neetephu zokuhlambela.

Iimveliso zasekhaya: Unokufumana isinyithi esicwecwe rhoqo kumaqhina kunye nolawulo olufakwe kwizixhobo ezahlukeneyo zendlu kunye nezixhobo zombane.Ukusebenzisa iplastiki egqunywe ngentsimbi kubiza kancinci kunokuvelisa amaqhina entsimbi yonke kwaye kukhuseleke ngakumbi.

Ukuba unayo naziphi na iiprojekthi ezizayo i-abs electroplating kwaye ifuna le teknoloji.NdiyacelaQhagamshelana nathi!Sinokubonelela ngetekhnoloji yobuchwephesha kwi-electroplating ukukunceda.

Ixesha lokuposa: Mar-15-2024