Ngexesha lenkqubo yokubumba, kuqhelekile ukudibana neziphene ezahlukeneyo kwiindawo ezibunjiweyo, ezinokuchaphazela umgangatho kunye nokusebenza kweemveliso.Eli nqaku lijolise ekuphononongeni ezinye iziphene eziqhelekileyo kwiindawo ezibunjiweyo zokutofa kunye nokuxoxa ngeendlela zokujongana nale miba.

1.Amanqaku okuHamba:

Imigca equkuqelayo ziziphene zokuthambisa eziphawulwa ngemigca engafakwanga mbala, imigca, okanye iipateni ezithi zibonakale kumphezulu wendawo ebunjiweyo.Le migca yenzeke xa iplastiki etyhidiweyo ishukuma ngesantya esahlukileyo kulo lonke uhlobo lwesitofu, okukhokelela kumazinga ahlukeneyo okuqiniswa kweresin.Imigca ehambayo idla ngokuba luphawu lwesantya esisezantsi sokutofa kunye/okanye uxinzelelo.

Ukongezelela, imigca yokuhamba inokuvela xa i-resin ye-thermoplastic ihamba kwiindawo zokubumba ezinobunzima obuhlukeneyo bodonga.Ke ngoko, ukugcina ubukhulu bodonga olungaguquguqukiyo kunye nokuqinisekisa ubude obufanelekileyo bee-chamfers kunye neefayili kubalulekile ukunciphisa ukwenzeka kwemigca yokuhamba.Esinye isilinganisi esisebenzayo sibeka isango kwindawo encinci ye-cavity yesixhobo, esiza ukunciphisa ukubunjwa kwemigca yokuhamba.

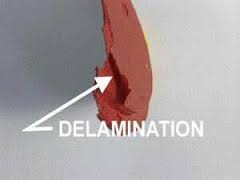

2. Ukupheliswa koMphezulu:

I-Delamination ibhekiselele ekwahlukaneni kweeleya ezibhityileyo kumphezulu wenxalenye, efana neengubo ezicwebekileyo.Le meko yenzeka ngenxa yobukho bezinto ezingcolileyo ezingezizo kwizinto eziphathekayo, ezikhokelela kwiimpazamo zendawo.I-Delamination inokubangelwa kukuthembela ngokugqithisileyo kwii-arhente zokukhulula ukungunda.

Ukujongana nokuthintela i-delamination, kuyacetyiswa ukuba kunyuswe ubushushu bomngundo kwaye kwandiswe inkqubo yokukhupha umngundo ukunciphisa ukuthembela kwiiarhente zokukhulula ukungunda, njengoko ezi arhente zinokuba negalelo kwi-delamination.Ukongeza, ukomiswa ngokucokisekileyo kwangaphambili kweplastiki ngaphambi kokubunjwa kunokunceda ekuthinteleni ukubola.

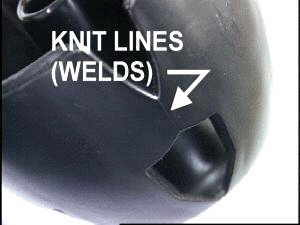

3. Imigca edityanisiweyo:

Imigca edityanisiweyo, ekwaziwa ngokuba yimigca yeweld, ziziphene ezenzeka xa ukuqukuqela ezibini zentlaka etyhidiweyo zidibana njengoko zihamba kwijometri yokungunda, ngakumbi kwiindawo ezinemingxuma.Xa iplastiki ihamba kwaye ijikeleze icala ngalinye lomngxuma, zombini ezo zihamba ziyadibana.Ukuba iqondo lokushisa le-resin etyhidiweyo alilona lifanelekileyo, ukuhamba ezimbini kunokungaphumeleli ukudibanisa ngokufanelekileyo, okukhokelela kumgca we-weld obonakalayo.Lo mgca we-weld unciphisa amandla onke kunye nokuqina kwecandelo.

Ukuthintela inkqubo yokuqiniswa kwangaphambi kwexesha, kunenzuzo ukwandisa ubushushu be-resin etyhidiweyo.Ngaphezu koko, ukunyusa isantya sokutofa kunye noxinzelelo kunokunceda ukunciphisa ukwenzeka kwemigca edityanisiweyo.I-resin ezine-viscosity ephantsi kunye namanqaku aphantsi okunyibilika aphantsi kwengxaki yokubunjwa komgca we-weld ngexesha lokubumba inaliti.Ukongezelela, ukususa izahlulo kuyilo lokubumba kunokuphelisa ukubunjwa kwemigca ye-weld.

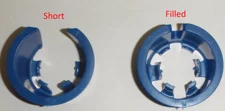

4. IiShots ezimfutshane:

Ukudubula okufutshane kwenzeka xa i-resin ihluleka ukuzalisa ngokupheleleyo i-mold cavity, okukhokelela kwiindawo ezingaphelelanga kunye nezingenakusebenziseka.Izinto ezahlukeneyo zinokubangela ukudubula okufutshane ekubumbeni inaliti.Izizathu eziqhelekileyo zibandakanya ukuhamba okuthintelweyo ngaphakathi kokungunda, okunokuthi kubangelwa kumasango amancinci okanye avaliweyo, iipokotho zomoya ezivalelekileyo, okanye uxinzelelo olungonelanga lwenaliti.I-viscosity yezinto eziphathekayo kunye nobushushu bomngundo bunokuba negalelo kwimifanekiso emfutshane.

Ukuthintela ukwenzeka kweeshots ezimfutshane, kunenzuzo ukunyusa izinga lokushisa lokungunda, njengoko oku kunokuphucula ukuhamba kwe-resin.Ukongeza, ukudibanisa ukungena okongeziweyo kuyilo lokubumba kuvumela umoya ovalelweyo ukuba ubaleke ngokufanelekileyo.Ngokujongana nale miba, ukubakho kokudubula okufutshane ekubumbeni inaliti kunokuncitshiswa.

5. Ukulwa:

I-Warping ekubumbeni inaliti ibhekiselele ekujikeni okungalindelekanga okanye ukugoba kwindawo ebangelwa kukushwabana kwangaphakathi okungalinganiyo ngexesha lenkqubo yokupholisa.Esi siphene ngokuqhelekileyo sivela ekupholiseni okungafaniyo okanye okungahambelaniyo kokungunda, okukhokelela kwisizukulwana soxinzelelo lwangaphakathi ngaphakathi kwezinto. ukuze izinto zipholile ngokufanayo.Ukugcina ubungakanani obufanayo bodonga kuyilo lokungunda kubalulekile ngenxa yezizathu ezininzi, kubandakanya ukuququzelela ukuhamba kakuhle kweplastiki ngomngxuma wokungunda kwicala elingaguquguqukiyo. Ngokuphumeza amaqhinga okupholisa afanelekileyo kunye nokuyila imibumba enobunzima obufanayo bodonga, umngcipheko weziphene ze-warpage ukubunjwa kwenaliti kunokuncitshiswa, okukhokelela kumgangatho ophezulu kunye neendawo ezizinzileyo.

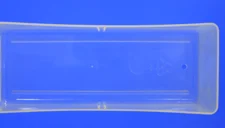

6. Ukutshiza:

Iziphene zeJetting ekubumbeni inaliti zingenzeka xa inkqubo yokuqinisa ingalingani.I-Jetting yenzeke xa ijethi yokuqala ye-resin ingena kubumba kwaye iqala ukuqina ngaphambi kokuba umgobo uzaliswe ngokupheleleyo.Oku kubangela iipateni ezibonakalayo zokuhamba kwe-squiggly kumphezulu wenxalenye kunye nokunciphisa amandla ayo.

Ukuthintela iziphene ze-jetting, kuyacetyiswa ukuba unciphise uxinzelelo lwenaliti, uqinisekise ukuzaliswa ngokuthe ngcembe kwesikhunta.Ukonyusa iqondo lobushushu lokungunda kunye neresin kunokunceda ukuthintela ukuqina kwangaphambili kweejethi zeresin.Ukongeza, ukubeka isango lokutofa ngendlela elawula ukuhamba kwezinto ngeyona ndlela imfutshane yokubumba yindlela esebenzayo yokunciphisa ijetting.

Ngokuphumeza la manyathelo, umngcipheko we-jetting defects ekubunjweni kwenaliti unokuncitshiswa, okukhokelela kumgangatho ophuculweyo womphezulu kunye nokomelezwa kwamandla enxalenye.

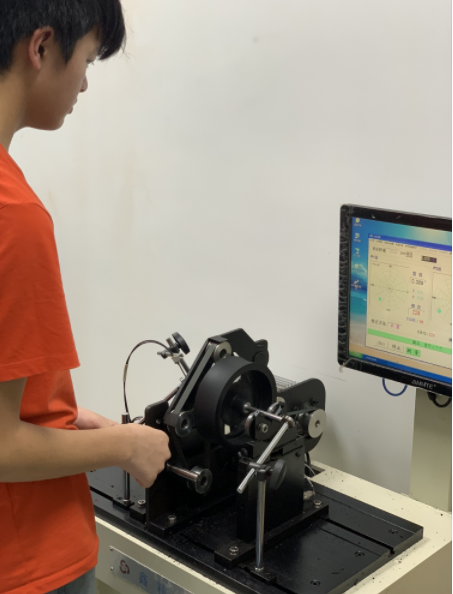

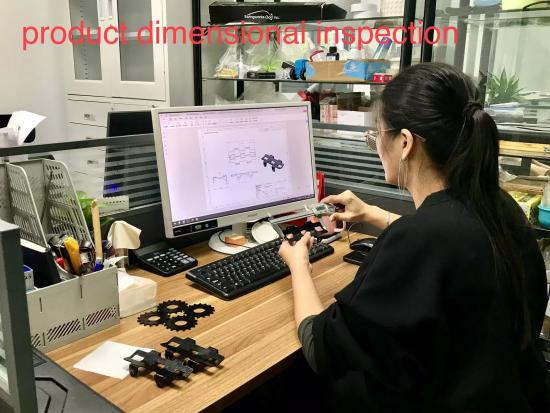

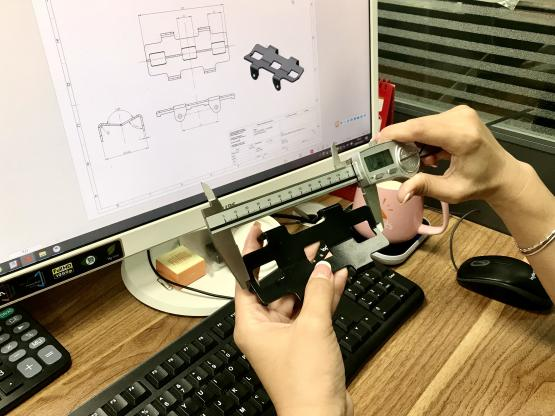

Inkampani yethu ithatha amanyathelo amaninzi ukuthintela iziphene zokubumba inaliti kunye nokuqinisekisa iindawo ezibunjiweyo ezikumgangatho ophezulu.Imiba ephambili ibandakanya ukukhetha izixhobo zeprimiyamu, uyilo lokubumba ngobunono, ulawulo oluchanekileyo lweeparamitha zenkqubo, kunye nolawulo olungqongqo lomgangatho.Iqela lethu lifumana uqeqesho lobungcali kwaye ngokuqhubekayo liphucula kwaye liphucula inkqubo yemveliso.

Inkampani yethu ithatha amanyathelo amaninzi ukuthintela iziphene zokubumba inaliti kunye nokuqinisekisa iindawo ezibunjiweyo ezikumgangatho ophezulu.Imiba ephambili ibandakanya ukukhetha izixhobo zeprimiyamu, uyilo lokubumba ngobunono, ulawulo oluchanekileyo lweeparamitha zenkqubo, kunye nolawulo olungqongqo lomgangatho.Iqela lethu lifumana uqeqesho lobungcali kwaye ngokuqhubekayo liphucula kwaye liphucula inkqubo yemveliso.

Inkampani yethu iqinisekisa umgangatho wemveliso ngokulandela inkqubo yolawulo lomgangatho we-ISO 9001.Siye saseka inkqubo yolawulo lomgangatho olubanzi kunye neenkqubo ezisemgangathweni kunye neenkqubo.Sikhuthaza ukuthatha inxaxheba kwabasebenzi kwaye sibonelela ngoqeqesho nemfundo.Ngala manyathelo, siqinisekisa ukuba iimveliso zethu ezithunyelweyo zinomgangatho obalaseleyo kwaye ziyahlangabezana neemfuno zabathengi.

Ukukhetha iqabane elenza izinto ezifana no-xiamenruicheng, onolwazi olubanzi lweziphene zokubumba inaliti kunye nesisombululo sazo, kungenza impembelelo enkulu kwisiphumo seprojekthi yakho.Isenokuba yeyona nto imiselayo phakathi kokufumana iindawo ezikumgangatho ophezulu, eziziswe ngeshedyuli nangaphakathi kohlahlo lwabiwo-mali, okanye ukuhlangabezana nemiba efana nemigca ye-weld, ijethi, iflash, amanqaku e-sink, kunye nezinye iziphene.Ngaphandle kobuchule bethu njengevenkile esekwe kwimfuno yokwenziwa kwemveliso, sikwabonelela ngoyilo lokubonisana kunye neenkonzo zokuphucula.Oku kuqinisekisa ukuba sincedisa iqela ngalinye ekwenzeni izinto ezisebenzayo, ezikholisayo, kunye nezinentsebenzo ephezulu ngokugqibeleleyo.Qhagamshelana nathi namhlanje ukuze ujonge izisombululo zethu ezibanzi zokubumba inaliti.

Ixesha lokuposa: Dec-15-2023