Isitofu sokubumba umphezulu ogqityiweyo ngokwe-SPI kunye neenkqubo zokuhlela ze-VDI-Iglosi, i-semi-gloss, imatte kunye nokugqitywa komphezulu owenziweyo.

Iziqulatho ezichazwe kweli nqaku

- Zeziphi iziqendu zokubumba umphezulu wesitofu?

- Kutheni kufuneka usebenzise izinto ezigqityiweyo xa ubumba inaliti?

- Isitofu sokungunda isixhobo sokugqiba iinkcukacha

- SPI Isitofu sokubumba umphezulu wokugqiba

- I-VDI Isitofu sokubumba umphezulu wokugqiba

- Unokukhetha njani umphezulu wokubumba isitofu esifanelekileyo?

Zeziphi iziqendu zokubumba umphezulu wesitofu?

Injection ukubumba umphezulu ukugqibaibalulekile kuyilo lwenxalenye oluyimpumelelo kwaye isetyenziselwa ubuhle kunye nezizathu ezisebenzayo kwiindawo zokubumba iinaliti zeplastiki kwiimveliso zobunjineli.Ukugqitywa komphezulu kuphucula inkangeleko kunye nokuvakalelwa kwemveliso njengoko ixabiso eliboniweyo kunye nomgangatho wemveliso yanda ngokugqitywa kwendawo efanelekileyo.

Isitya sePlastiki (Umthombo : XR USA Client )

Kutheni kufuneka usebenzise izinto ezigqityiweyo xa ubumba inaliti?

Ukwandisa inxalenye yobuhle

Abaqulunqi bamacandelo banokusebenzisa iindlela zokuthungwa kwiinjongo ezahlukeneyo zobuhle.I-texture egudileyo okanye i-matte surface iphucula inkangeleko yayo kwaye inika imbonakalo ephucukileyo.Ikwagquma iimpazamo eziveliswe sisitofu sokubumba, esifana namanqaku omatshini wokwenza izixhobo, amanqaku e-sink, imigca ye-weld, i-flow lines, kunye nokuphawula izithunzi.Amacandelo anomgangatho ogqwesileyo womphezulu abhenela ngakumbi kubathengi ngokwembono yeshishini.

Ukuphucula ukusebenza kwenxalenye

Ngaphandle koqwalaselo lobuhle oluya ekukhetheni umphezulu wokubumba umphezulu wenaliti, kukwakho nokuqwalaselwa okubalulekileyo okusebenzayo.

Uyilo lusenokufuna ukubamba okuqinileyo ukuze usebenze ngokugqibeleleyo.Iziqendu zeplastiki ezixutyiweyo ziphucula umgangatho wokubamba.Yiyo loo nto unyango lokubumba umphezulu wonyango lusetyenziswa rhoqo kwiimveliso ezikwaziyo ukutyibilika.Umngundo owenziweyo unokunceda ekubalekeni kweegesi ezivalelekileyo.

Ukugqitywa komphezulu we-SPI ogudileyo kunokubangela ukuba ipeyinti ixobuke.Nangona kunjalo, indawo enqabileyo inokuqinisekisa ukuba ipeyinti ibambelela bhetele kwinto ebunjiweyo.Unyango lomphezulu we-SPI owenziweyo wonyusa amandla enxalenye kunye nokhuseleko.

Ubume buneenzuzo ezininzi, kuquka:

- Ukuqhekeka kweplastiki—Ezi kreyizi zinokususwa ngokongeza ubungqingqwa bemixholo ngelixa ukhulisa amandla kunye neempawu ezingatyibiliki.

- Ukubambelela okuphuculweyo-Ukongeza ukuthungwa kwecandelo kwenza ukuphatha kube lula, ukwandisa ukusebenziseka kunye nokhuseleko kwizicelo ezithile.

- Ukunamathela kwepeyinti-Ipeyinti ibambelela ngokuqinileyo kwinto eyenziweyo ngexesha lokubumba okulandelayo.

- Ukwenza ii-undercuts-Ukuba unesabelo esingaguqukiyo ukuza kwisiqingatha esishukumayo sokungunda, ukuthumela umbhalo kuyo nayiphi na indawo kunokubonelela nge-pu eyimfuneko.ll.

Isitofu sokungunda isixhobo sokugqiba iinkcukacha

Eyona ndlela iqhelekileyo yokuchaza imiphezulu yokubumba inaliti kukusebenzisaI-PIA (okanye iSPI), VDIkwayeMold-techimigangatho.Abenzi bezixhobo zokubumba, abavelisi kunye neenjineli zokuyila kwihlabathi jikelele bayayiqaphela le migangatho mithathu kunye nemigangatho yePIA ixhaphake kakhulu kwaye yaziwa ngokubanzi ngokuba "ngamabakala eSPI".

Ukugqitywa kweglosi – kwiBanga A – Ukugqiba kwedayimani

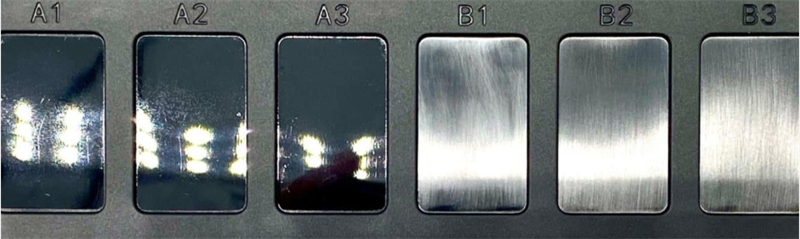

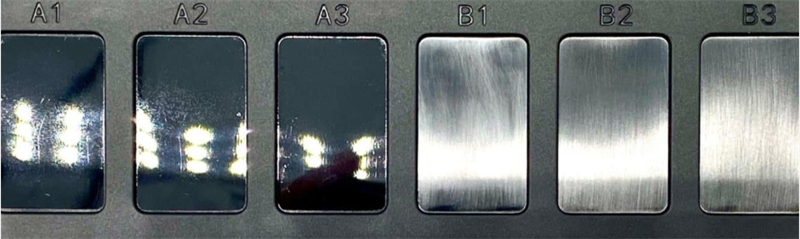

(SPI-AB Isitofu-ukubumba umphezulu ogqityiweyo)

Ezi ziqu zebakala “A” zigudile, ziyakhazimla, kwaye zezona zibiza kakhulu.La mabanga aya kufuna izixhobo eziqinileyo zokubumba zentsimbi, ezithi zigqunywe kusetyenziswa amanqanaba ahlukeneyo edayimani.Ngenxa yokuncamathela okucokisekileyo okuziinkozo kunye nendlela yokupolisha ejikelezayo engacwangciswanga, ayizukuba nokwakheka okucacileyo kunye nokusasaza imitha yokukhanya, inika ukugqiba okukhazimlayo.Ezi zikwabizwa ngokuba "yiDiamond finish" okanye "buff finish" okanye "A finish"

| Gqiba | Umgangatho weSPI | Gqibezela Indlela | Uburhabaxa boMphezulu (Ixabiso likaRa) |

| Gqibezela Kakhulu Elikhazimlayo | A1 | 6000 Grit diamond buff | 0.012 ukuba 0.025 |

| Gqibezela ngokukhazimlayo okuphezulu | A2 | 3000 Grit diamond buff | 0.025 ukuba 0.05 |

| Gqibezela ngokuGqeba okuQhelekileyo | A3 | 1200 Grit diamond buff | 0.05 ukuya o.1 |

Amabakala eglosi e-SPI afanelekile kwiimveliso ezinomphezulu ogudileyo wokugqiba ngenxa yezizathu zokuthambisa kunye nokusebenza.Umzekelo, i-A2 yeyona nto ixhaphakileyo yedayimane egqityiweyo kwishishini, ekhokelela kwiindawo ezintle ezibonwayo ezinokukhutshwa okuhle.Ukongeza, umgangatho "A" wokugqitywa usetyenziswa kwiindawo ezibonakalayo ezifana neelensi, izibuko, kunye neevisor.

Ukugqiba kwesiqingatha seglosi – kwiBanga B

(umzobo 2.SPI-AB Isitofu-ukubumba umphezulu ogqityiweyo)

Ezi zigqibo ze-semi-gloss zilungile ekususeni ukwenziwa komatshini, ukubumba, kunye namanqaku esixhobo ngexabiso elifanelekileyo lezixhobo.Ezi zigqibo zomphezulu ziveliswa kusetyenziswa amabanga ahlukeneyo eesanti ezisetyenziswa ngokushukuma komgca, enika ipateni yomgca njengoko kubonisiwe kumfanekiso wesi-2.

| Gqiba | Umgangatho weSPI | Gqibezela Indlela | Uburhabaxa boMphezulu (Ixabiso likaRa) |

| Fine Semi Gqibezela Gqiba | B1 | 600 Grit Paper | 0.05 ukuya ku-0.1 |

| Phakathi Semi Gqibezela Gqiba | B2 | 400 Grit Paper | 0.1 ukuya ku-0.15 |

| Eqhelekileyo emi Glossy Gqiba | B3 | 320 Iphepha lokuGritha | 0.28 ukuya o.32 |

I-SPI(B 1-3) isiqingatha segloss umphezulu ogqityiweyo uya kunika inkangeleko entle ebonakalayo kwaye isuse iimpawu zesixhobo sokungunda.Ezi zisoloko zisetyenziswa kwiindawo ezingeyiyo into yokuhombisa okanye ebonakalayo ebalulekileyo kwimveliso.

Ukugqiba kakuhle – kwiBanga C

Ezi zezona zigqityiweyo zoqoqosho kunye nezithandwayo, ezikhazimliswe kusetyenziswa umgubo ocolekileyo wamatye.Ngamanye amaxesha kuthiwa ukugqiba kwamatye, kunika ukukhululwa okulungileyo kwaye kunceda ukufihla amanqaku omatshini.IBakala C likwalinyathelo lokuqala lokugqibezela umgangatho weBakala A no-B.

| Gqiba | Umgangatho weSPI | Gqibezela Indlela | Uburhabaxa boMphezulu (Ixabiso likaRa) |

| Medium Matte Gqiba | C1 | 600 Grit Stone | 0.35 ukuya ku-0.4 |

| Medium Matte Gqiba | C2 | 400 Grit Paper | 0.45 ukuba 0.55 |

| UkuQeda kweMatte eqhelekileyo | C3 | 320 Iphepha lokuGritha | 0.63 ukuba 0.70 |

Ukugqiba okubhaliweyo - iBanga D

Inika inxalenye yembonakalo yobuhle obubonakalayo kwaye isetyenziswa ngokubanzi kwiindawo zoshishino kunye nempahla yabathengi.Ezi zilungele iinxalenye ezingenazo iimfuneko ezithile ezibonakalayo.

| Gqiba | Umgangatho weSPI | Gqibezela Indlela | Uburhabaxa boMphezulu (Ixabiso likaRa) |

| Ukugqitywa kwe-Satin Texture | D1 | 600 ilitye phambi komile intsimbi yeglasi#11 | 0.8 ukuya 1.0 |

| UkuGqiba koBume obumileyo | D2 | 400 ilitye phambi kweglasi eqhumayo eyomileyo #240 oxide | 1.0 ukuya ku-2.8 |

| UkuGqiba kobume oburhabaxa | D3 | 320 ilitye phambi kokuqhuma okomileyo #24 oxide | 3.2 ukuba 18.0 |

Akukho mntu wakha wathi ukuyila kunye nokwenza iindawo ezibunjiweyo kulula.Injongo yethu kukukufumana ngokukhawuleza kunye namalungu asemgangathweni.

I-VDI Isitofu sokubumba umphezulu wokugqiba

I-VDI 3400 Surface Finish (eyaziwa ngokuba yi-VDI surface finish) ibhekiselele kumgangatho wokubumba owenziwe nguVerein Deutscher Ingenieure (VDI), uMbutho weeNjineli zaseJamani.I-VDI 3400 yokugqiba umphezulu icutshungulwa ngokuyintloko yi-Electrical Discharge Machining (EDM) xa umatshini wokubumba.Isenokwenziwa nangendlela yesiqhelo yokuthumela imiyalezo (njengakwiSPI).Nangona imigangatho isekwe luluntu lweeNjineli zaseJamani iqhele ukusetyenziswa phakathi kwabenzi bezixhobo kuyo yonke indawo, kubandakanya uMntla Melika, iYurophu kunye neAsia.

Amaxabiso e-VDI asekelwe kuburhabaxa bomphezulu.Ukusuka emfanekisweni, sibona ukuthungwa okuhlukeneyo komphezulu ogqityiweyo kunye namaxabiso ahlukeneyo obunzima bomphezulu.

| Ixabiso leVDI | Inkcazo | Usetyenziso | Uburhabaxa bobuso (Ra µm) |

| 12 | 600 Ilitye | Amalungu epolisi ephantsi | 0.40 |

| 15 | 400 Ilitye | Amalungu epolisi ephantsi | 0.56 |

| 18 | Dry Blast Glass Bead | Satin ukugqiba | 0.80 |

| 21 | Ukudubula okomileyo # 240 i-Oxide | Ukugqiba ngokukhawuleza | 1.12 |

| 24 | Ukudubula okomileyo # 240 i-Oxide | Ukugqiba ngokukhawuleza | 1.60 |

| 27 | Ukudubula okomileyo # 240 i-Oxide | Ukugqiba ngokukhawuleza | 2.24 |

| 30 | Ukudubula okomileyo # 24 i-Oxide | Ukugqiba ngokukhawuleza | 3.15 |

| 33 | Ukudubula okomileyo # 24 i-Oxide | Ukugqiba ngokukhawuleza | 4.50 |

| 36 | Ukudubula okomileyo # 24 i-Oxide | Ukugqiba ngokukhawuleza | 6.30 |

| 39 | Ukudubula okomileyo # 24 i-Oxide | Ukugqiba ngokukhawuleza | 9.00 |

| 42 | Ukudubula okomileyo # 24 i-Oxide | Ukugqiba ngokukhawuleza | 12.50 |

| 45 | Ukudubula okomileyo # 24 i-Oxide | Ukugqiba ngokukhawuleza | 18.00 |

Ukuqukumbela

Kwiindidi ezimbini zomphezulu wokubumba inaliti, i-SPI ibakala A no-B zithathwa njengezona zigudileyo ezinoburhabaxa obuphantsi kakhulu kwaye zibiza kakhulu.Ngelixa, ukusuka kwindawo yokujonga uburhabaxa, i-VDI 12, eyona VDI yomgangatho ophezulu, ilingana ne-SPI C grade.

Akukho mntu wakha wathi ukuyila kunye nokwenza iindawo ezibunjiweyo kulula.Injongo yethu kukukufumana ngokukhawuleza kunye namalungu asemgangathweni.

Unokukhetha njani umphezulu wokubumba isitofu esifanelekileyo?

Khetha umphezulu wokubumba isitofu ngokuqwalasela umsebenzi wenxalenye, imathiriyeli esetyenzisiweyo, kunye neemfuno zokubonwayo.Uninzi lwemathiriyeli ebunjiweyo yenaliti yeplastiki inokuba neentlobo ezahlukeneyo zokugqitywa komphezulu.

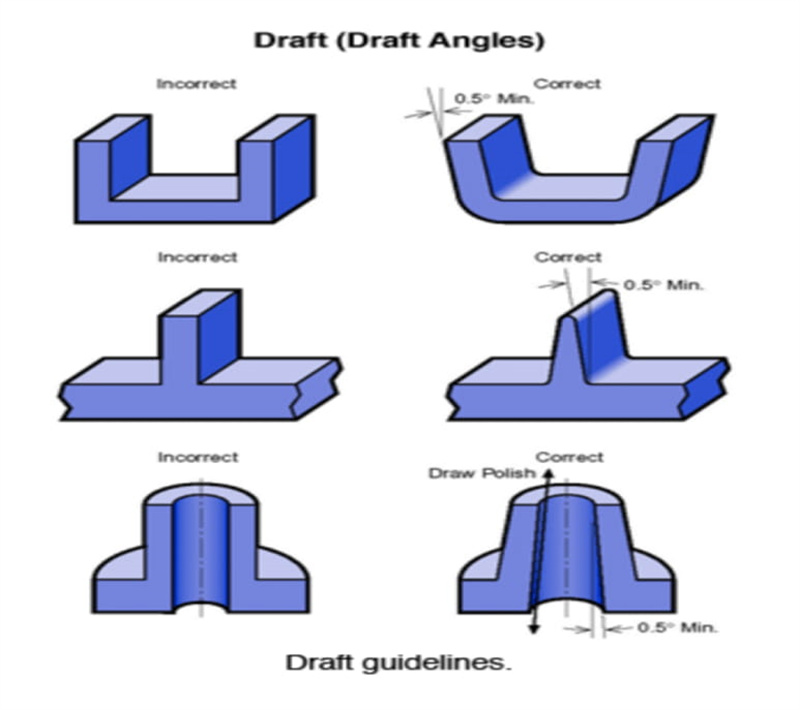

Ukhetho lokugqitywa komphezulu kufuneka lusekwe kwisigaba sokuqala soyilo loyilo lwemveliso kuba umphezulu uyalela ukukhetha izinto kunye ne-engile eyidrafti, ephembelela iindleko zezixhobo.Umzekelo, ikhosi okanye ukugqiba okuthungwe kufuna i-engile eyidrafti ebaluleke ngakumbi ukuze inxalenye ikhutshiwe kubumba.

Ke zeziphi ezona zinto ziphambili ekufuneka uziqwalasele xa ukhetha umphezulu ogqityiweyo wokubumba iiplastiki zokutofa?

Ukugqiba ukumenyezela kwiBanga A (Umthombo:XR USA Client)

Ixabiso lezixhobo

Ukugqitywa komphezulu kunye nezixhobo zinempembelelo enkulu kuyilo lwesixhobo kunye neendleko, ngoko ke qwalasela kwaye uvavanye ukusebenza ngokomphezulu kwangethuba kuyilo lomfanekiso.Ukuba ukugqitywa komphezulu kubaluleke kakhulu ekusebenzeni kwayo, qwalasela ukugqitywa komphezulu kwinqanaba leengcamango zoyilo lwemveliso.

Iindawo ezininzi zenkqubo yokubumba inaliti ziye zazenzekela, kodwa ukupolisha kuhlukile.Yeyona milo ilula kuphela enokuthi ipoliswe ngokuzenzekelayo.IiPolishers ngoku zinezixhobo ezingcono kunye nemathiriyeli yokusebenza nazo, kodwa inkqubo ihleli ifuna abasebenzi abaninzi.

I-engile yoyilo

Uninzi lwaMalungu afuna i-engile eyi-Drafti ye-1½ ukuya kwi-2 Degrees

Lo ngumgaqo webhontsi osebenza kwiindawo ezibunjiweyo ezinobunzulu obufikelela kwi-intshi ezi-2.Ngobu bukhulu, idrafti emalunga ne-1½ degrees yanele ukukhutshwa lula kwamalungu kubumba.Oku kunceda ukuthintela umonakalo kwiindawo xa izinto ze-thermoplastic ziyancipha.

Isixhobo sesixhobo sokungunda

Isixhobo sokubumba sichaphazela kakhulu ukuguda komphezulu wenaliti yokubumba.Ukungunda kunokwenziwa ngeentsimbi ezahlukeneyo, nangona intsimbi kunye ne-aluminiyam zezona zidumileyo.Iziphumo zezi zinyithi zimbini kwizinto ezibunjiweyo zeplastiki zahluke kakhulu.

Ngokubanzi, intsimbi yesixhobo esiqinileyo inokuvelisa ukugqiba kweplastiki egudileyo xa kuthelekiswa nezixhobo ze-aluminium alloy.Yiyo loo nto qwalasela ukubumba kwentsimbi ukuba amaqhekeza anomsebenzi wobuhle ofuna inqanaba eliphantsi loburhabaxa bomphezulu.

Izinto zokubumba

Uluhlu olubanzi lweeplastiki zokubumba inaliti ziyafumaneka ukugubungela zonke iintlobo zamalungu kunye nemisebenzi.Nangona kunjalo, ayizizo zonke iiplastiki ezinokufikelela kwinqanaba elifanayo lokubumba umphezulu.Ezinye iipholima zifaneleka ngcono ukugqibezela okugudileyo, ngelixa ezinye zifaneleka ngcono ukurhabaxa kwindawo ebhalwe ngaphezulu.

Iimpawu zekhemikhali nezomzimba ziyahluka phakathi kwezinto zokubumba inaliti.Ubushushu obunyibilikayo, umzekelo, ngumba obalulekileyo kwisakhono semathiriyeli ukunika umgangatho othile womphezulu.Izongezo nazo zinempembelelo kwisiphumo semveliso egqityiweyo.Ngenxa yoko, kubalulekile ukuvavanya izixhobo ezahlukeneyo ngaphambi kokuthatha isigqibo malunga nokuthungwa komphezulu.

Ngaphaya koko, izongezo zemathiriyeli ezifana nokugcwaliswa kunye neepigments zinokuchaphazela umphezulu wento ebunjiweyo.Iitheyibhile ezikwicandelo elilandelayo zibonisa ukusebenza kwezixhobo ezininzi zokubumba zokutofa kwii-SPI ezahlukeneyo zokutyunjwa.

Ukufaneleka kwezinto eziphathekayo kwiBanga le-SPI-A yokugqiba umphezulu

| Izinto eziphathekayo | A-1 | A-2 | A-3 |

| ABS | I-avareji | I-avareji | Kulungile |

| Iipolypropylene (PP) | Ayikhuthazwa | I-avareji | I-avareji |

| Ipolystyrene (PS) | I-avareji | I-avareji | Kulungile |

| HDPE | Ayikhuthazwa | I-avareji | I-avareji |

| Inayiloni | I-avareji | I-avareji | Kulungile |

| Polycarbonate (PC) | I-avareji | Kulungile | Egqwesileyo |

| Ipolyurethane (TPU) | Ayikhuthazwa | Ayikhuthazwa | Ayikhuthazwa |

| I-acrylic | Egqwesileyo | Egqwesileyo | Egqwesileyo |

Ukufaneleka kwezinto eziphathekayo kwiBanga le-SPI-B lokugqiba umphezulu

| Izinto eziphathekayo | B-1 | B-2 | B-3 |

| ABS | Kulungile | Kulungile | Egqwesileyo |

| Iipolypropylene (PP) | Kulungile | Kulungile | Egqwesileyo |

| Ipolystyrene (PS) | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| HDPE | Kulungile | Kulungile | Egqwesileyo |

| Inayiloni | Kulungile | Egqwesileyo | Egqwesileyo |

| Polycarbonate (PC) | Kulungile | Kulungile | I-avareji |

| Ipolyurethane (TPU) | Ayikhuthazwa | I-avareji | I-avareji |

| I-acrylic | Kulungile | Kulungile | Kulungile |

Ukufaneleka kwezinto eziphathekayo kwiBanga le-SPI-C lokugqiba umphezulu

| Izinto eziphathekayo | C-1 | C-2 | C-3 |

| ABS | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| Iipolypropylene (PP) | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| Ipolystyrene (PS) | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| HDPE | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| Inayiloni | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| Polycarbonate (PC) | I-avareji | Ayikhuthazwa | Ayikhuthazwa |

| Ipolyurethane (TPU) | Kulungile | Kulungile | Kulungile |

| I-acrylic | Kulungile | Kulungile | Kulungile |

Ukufaneleka kwezinto eziphathekayo kwiBanga le-SPI-D lokugqiba umphezulu

| Izinto eziphathekayo | D-1 | D-2 | D-3 |

| ABS | Egqwesileyo | Egqwesileyo | Kulungile |

| Iipolypropylene (PP) | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| Ipolystyrene (PS) | Egqwesileyo | Egqwesileyo | Kulungile |

| HDPE | Egqwesileyo | Egqwesileyo | Egqwesileyo |

| Inayiloni | Egqwesileyo | Egqwesileyo | Kulungile |

| Polycarbonate (PC) | Egqwesileyo | Ayikhuthazwa | Ayikhuthazwa |

| Ipolyurethane (TPU) | Egqwesileyo | Egqwesileyo | Kulungile |

| I-acrylic | I-avareji | I-avareji | I-avareji |

Iiparamitha zokubumba

Isantya se-injection kunye nobushushu buchaphazela ukugqiba komhlaba ngenxa yezizathu ezimbalwa.Xa udibanisa isantya senaliti ekhawulezayo kunye nobushushu obuphezulu bokunyibilika okanye ubushushu bokungunda, isiphumo siya kuba siglosi okanye ukugudiseka komphezulu wenxalenye.Ngokwenyani, isantya sokutofa ngokukhawuleza siphucula ukuqaqamba kunye nokuguda.Ukongeza, ukuzaliswa ngokukhawuleza komgodi wokungunda kunokuvelisa imigca ye-weld engabonakaliyo kunye nomgangatho owomeleleyo wobuhle becala lakho.

Ukugqiba umphezulu wenxalenye yingqwalasela ebalulekileyo kuphuhliso lwemveliso iyonke kwaye kufuneka kucingwe ngexesha lenkqubo yoyilo ukufezekisa iziphumo ezifunwayo.Ngaba uyithathele ingqalelo isiphelo sokusetyenziswa kwesitofu sakho esibunjiweyo?

Vumela uXiamen Ruicheng akuncede uthathe isigqibo malunga nokugqitywa komphezulu ophucula ubuhle kunye nokusebenza kwenxalenye yakho.

Ixesha lokuposa: May-22-2023