Isitampu yinkqubo yokuvelisa esetyenziselwa ukubumba okanye ukwenza amashiti esinyithi okanye imicu ngokusebenzisa amandla ngokufa okanye uthotho lokufa.Kubandakanya ukusetyenziswa komshicileli, osebenzisa uxinzelelo kwizinto zetsimbi, ezibangela ukuba zikhubazeke kwaye zithathe ubume bokufa.

Ngawaphi amanyathelo enkqubo yesitampu?

① Uyilo kunye nobuNjineli: Inkqubo iqala ngoyilo kunye nobunjineli benxalenye yesitampu.Oku kubandakanya ukudala inxalenye yejometri, ukumisela iinkcukacha zemathiriyeli, kunye noyilo lokufa kunye nezixhobo ezifunekayo kwinkqubo yokunyathela.

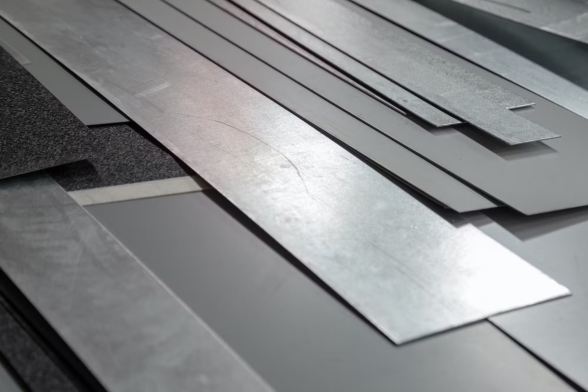

②Ukulungiswa kwezinto: Amaphepha esinyithi okanye imichilo, eyaziwa ngokuba yimpahla okanye izithuba ezingenanto, zilungiselelwe inkqubo yesitampu.Oku kunokubandakanya ukusika isitokhwe kubungakanani obufanelekileyo kunye nokumila ukuze kulingane iifa kunye nokususa naziphi na izinto ezingcolisa umphezulu okanye ukungafezeki.

③I-Die Setup: Iifa, eziquka i-punch kunye ne-die cavity, zifakwe kwi-pressing press.Iifazi zilungelelaniswe ngokuchanekileyo kwaye zibotshelelwe ngokukhuselekileyo endaweni ukuze kuqinisekiswe ukuba isitampu esichanekileyo nesingatshintshiyo.

④Ukutya: Impahla yesitokhwe ifakwa kumshicileli wesitampu, ngesandla okanye ngokuzenzekelayo.Indlela yokutya iqinisekisa ukuba isitokhwe sibekwe ngokufanelekileyo phantsi kweefayile kumjikelo ngamnye wesitampu.

⑤Ukusebenza kweStamping: Umshicileli wesitampu usebenzisa inani elibalulekileyo lamandla kwimpahla yesitokhwe, ebangela ukuba ikhubazeke kwaye ithathe ubume bomgodi wokufa.Eli nyathelo ngokuqhelekileyo libandakanya umsebenzi omnye okanye ngaphezulu, njengokuvala (ukusika umlo ofunekayo), ukugoba (ukwenza ii-angles okanye ii-curves), ukudweba (ukwelula izinto kwimilo enzulu), okanye ukwenza (ukudala iimpawu ezithile okanye iipatheni).

⑥Inxalenye yokuSuswa: Emva kokuba umsebenzi wesitampu ugqityiwe, indawo enesitampu iyasuswa ekufeni.Oku kunokwenziwa ngesandla okanye ngoncedo lwe-automation, njengeengalo zerobhothi okanye iinkqubo zokuhambisa.

⑦ Imisebenzi yesibini: Ngokuxhomekeke kwiimfuno ezithile zecandelo, imisebenzi eyongezelelweyo yesibini inokwenziwa.Oku kunokubandakanya ukuchithwa (ukususa imiphetho ebukhali okanye i-burrs), ukugqiba umphezulu (njengokupholisha okanye ukugquma), ukudibanisa, okanye ukuhlolwa komgangatho.

⑧Ukuhlolwa koMgangatho: Iindawo ezinesitampu zihlolwa ngokucokisekileyo ukuqinisekisa ukuba ziyahlangabezana nemigangatho yomgangatho echaziweyo.Oku kunokubandakanya imilinganiselo yobukhulu, uhlolo olubonakalayo, uvavanyo lwemathiriyeli, okanye ezinye iinkqubo zolawulo lomgangatho.

⑨Ukupakishwa kunye nokuThunyelwa: Emva kokuba iindawo ezigxininisiweyo zigqithise ukuhlolwa komgangatho, zipakishwe ngokweemfuno ezithile kwaye zilungiselelwe ukuthunyelwa okanye ukuqhutyelwa phambili.

Kubalulekile ukuqaphela ukuba amanyathelo achanekileyo enkqubo anokwahluka ngokuxhomekeke kubunzima benxalenye, indlela ekhethiweyo yokupakisha, kunye nezinye izinto ezithe ngqo kwi-setup yokuvelisa.

Jonga Yintoni eyenza ukuba isitampu sidume

Ixabiso elisebenzayo: Isitampu sinika inzuzo yeendleko ngenxa yokusebenza kwayo kakuhle kwemveliso.Inkqubo ivumela ukuveliswa ngokukhawuleza kunye nokuzenzekelayo kweenxalenye ezinkulu, ukunciphisa iindleko zabasebenzi kunye nokunyusa indleko-ngempumelelo.

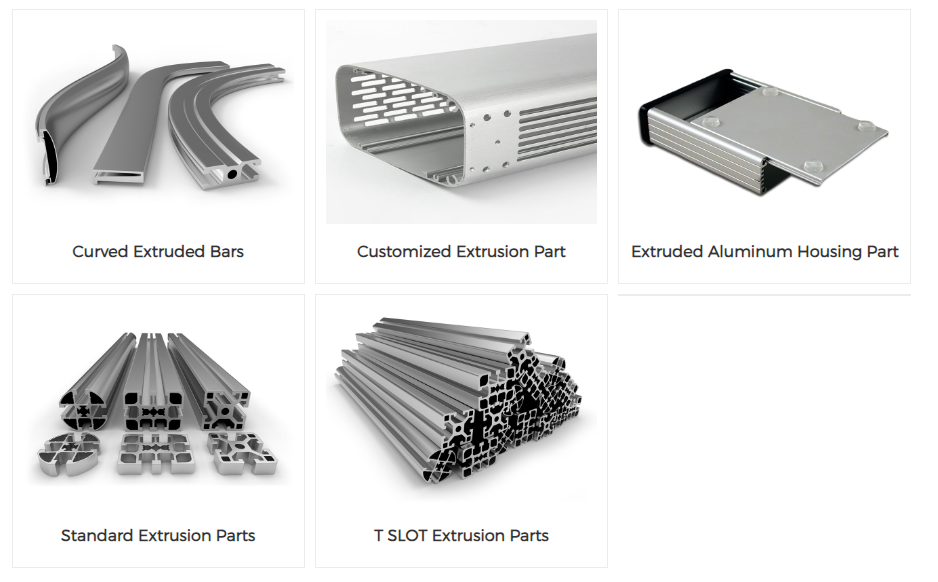

Ukuhambelana kwezinto: Isitampu sinokusetyenziswa kwizinto ezahlukeneyo, kuquka isinyithi (njengentsimbi, i-aluminiyam, nobhedu) kunye nezinye iiplastiki.Oku bhetyebhetye kuvumela abavelisi ukuba bakhethe eyona mathiriyeli ifanelekileyo kwiimfuno zabo zesicelo, bethathela ingqalelo imiba efana namandla, ukuqina, kunye nokuqhuba.

Ukuchaneka okuphezulu: Iinkqubo zesitampu zinokufikelela kumanqanaba aphezulu okuchaneka komda kunye nokuphindaphinda.Ngokusebenzisa izixhobo eziphambili kunye netekhnoloji yokufa, iindawo ezichanekileyo nezingaguqukiyo zinokuveliswa, ukuhlangabezana nokunyamezelana okuqinileyo kunye nemigangatho yomgangatho.

Isantya kunye nokuSebenza: Imisebenzi yesitampu idla ngokukhawuleza kwaye iyasebenza.Ngokutya okuzenzekelayo kunye neenkqubo zokushicilela, ukunyathela kunokufezekisa amazinga aphezulu emveliso, ukunciphisa amaxesha okukhokela kunye nokwandisa imveliso yonke.

Amandla kunye nokuqina: Iindawo ezinesitampu zihlala zibonisa iipropathi ezigqwesileyo zoomatshini, kubandakanya amandla, ukuqina, kunye nokuqina.I-deformation kunye nokuqina komsebenzi okwenzeka ngexesha lenkqubo yesitampu kuphucula ukunyaniseka kwesakhiwo samalungu, okwenza ukuba afanelekele izicelo ezibango.

I-Scalability: Isitampu sinokuthwala zombini iimfuno eziphantsi kunye neziphezulu zemveliso.Ifaneleka kakuhle kwimveliso yobuninzi ngenxa yesantya esiphezulu, iinkqubo ezizenzekelayo.Kwangaxeshanye, inokuthi ilungelelaniselwe imveliso encinci okanye iprototyping, ibonelela ngokuguquguquka ekuhlangabezaneni neemfuno ezahlukeneyo zokwenziwa.

Ukudityaniswa nezinye iinkqubo: Isitampu sinokudityaniswa lula kunye nezinye iinkqubo zokuvelisa ezifana ne-welding, indibano, kunye nokugqiba umphezulu.Oku kuvumela ukuhamba komsebenzi wemveliso olungelelanisiweyo kunye nokudalwa kweendibano ezinzima okanye iimveliso ezigqityiweyo.

Xa ukhetha inkqubo yesitampu ngokweyona meko, izinto ezininzi kufuneka ziqwalaselwe:

Material: Chonga uhlobo lwentsimbi okanye ialloyi ekufuneka isitampu.Iintsimbi ezahlukeneyo zineempawu ezahlukeneyo kunye neempawu, njengamandla, ukuqina, kunye nobukhulu.Qwalasela iimfuno ezithile zenxalenye okanye imveliso kwaye ukhethe inkqubo yesitampu efanelekileyo kwizinto ezikhethiweyo.

Ukuntsonkotha kweCandelo: Vavanya ukuntsonkotha kwenxalenye okanye uyilo lwemveliso.Qinisekisa ukuba ineemilo ezintsonkothileyo, ukugoba, okanye iimpawu ezinje ngokuhombisa okanye ukugqobhoza.Iinkqubo ezahlukeneyo zesitampu, ezifana nokuvala, ukugoba, okanye umzobo onzulu, zifanelekile kwiindidi ezahlukeneyo zejometri.

Umthamo weMveliso: Qwalasela umthamo ofunekayo wemveliso.Iinkqubo zesitampu zinokulungelelaniswa kwimveliso ephantsi kunye nephezulu.Kwimveliso yomthamo ophezulu, ukunyathela kwe-progressive die stamping okanye ukutshintshela isitampu kunokufaneleka, ngelixa i-volume ephantsi okanye imveliso yeprototype, inqanaba elinye okanye i-compound die stamping ingasetyenziswa.

Ukunyamezela kunye nokuchaneka: Vavanya ukuchaneka kwe-dimensional efunekayo kunye nokunyamezela inxalenye yesitampu.Ezinye iinkqubo zesitampu, ezifana nokuvala izinto kakuhle okanye ukucofa isitampu ngokuchanekileyo, zinokunyamezela ukunyamezelana nokuchaneka okuphezulu xa kuthelekiswa neenkqubo ezisemgangathweni.Qwalasela inqanaba lokuchaneka okufunekayo kwinxalenye ethile okanye imveliso.

Ukugqitywa komphezulu: Vavanya ukugqitywa komphezulu ofunekayo wenxalenye egximfiziwe.Iinkqubo ezithile zesitampu zinokushiya amanqaku okanye zifune amanyathelo okugqiba ongezelelweyo ukufikelela kumgangatho ofunekayo womphezulu.Qwalasela ukuba ngaba imisebenzi yesibini efana nokuchithwa okanye ukupolisha iyafuneka.

Izixhobo kunye neZixhobo: Vavanya ukufumaneka kunye neendleko zezixhobo kunye nezixhobo ezifunekayo kwinkqubo yokupakisha.Iinkqubo ezahlukeneyo zesitampu zinokufuna ukufa okukhethekileyo, iingqindi, okanye izixhobo zokushicilela.Qwalasela ixesha elikhokelayo kunye neendleko zezixhobo zokusebenza, kunye nokuba nokwenzeka kokufumana okanye ukuguqula izixhobo eziyimfuneko.

Iindleko kunye nokusebenza kakuhle: Vavanya ukuphumelela kweendleko kunye nokusebenza kakuhle kwenkqubo yesitampu.Qwalasela izinto ezifana neendleko zempahla, iindleko zezixhobo, ixesha lomjikelo wemveliso, ukusetyenziswa kwamandla, kunye neemfuno zabasebenzi.Thelekisa iingenelo kunye nemida yeenkqubo ezahlukeneyo zokutywina ukuze ubone olona khetho lungabizi kakhulu kwiimfuno ezithile zemveliso.

Ngokuqwalasela ngononophelo le miba kunye nokubonisana neengcaphephe kwinkalo yesitampu, ezifana ne-xiamenruicheng, unokwenza isigqibo esinolwazi kwaye ukhethe eyona nkqubo ifanelekileyo yokucofa imeko yakho.

Ixesha lokuposa: Feb-21-2024