I-Die casting yinkqubo yokuphosa isinyithi apho isinyithi esinyibilikisiweyo, ngokuqhelekileyo i-alloy engeyiyo i-ferrous efana ne-aluminiyam, i-zinc, okanye i-magnesium, ifakwe phantsi koxinzelelo oluphezulu kwi-mold yentsimbi enokusetyenziswa kwakhona, ebizwa ngokuba yi-die.Idayi yenzelwe ukwenza imilo enqwenelekayo yemveliso yokugqibela.

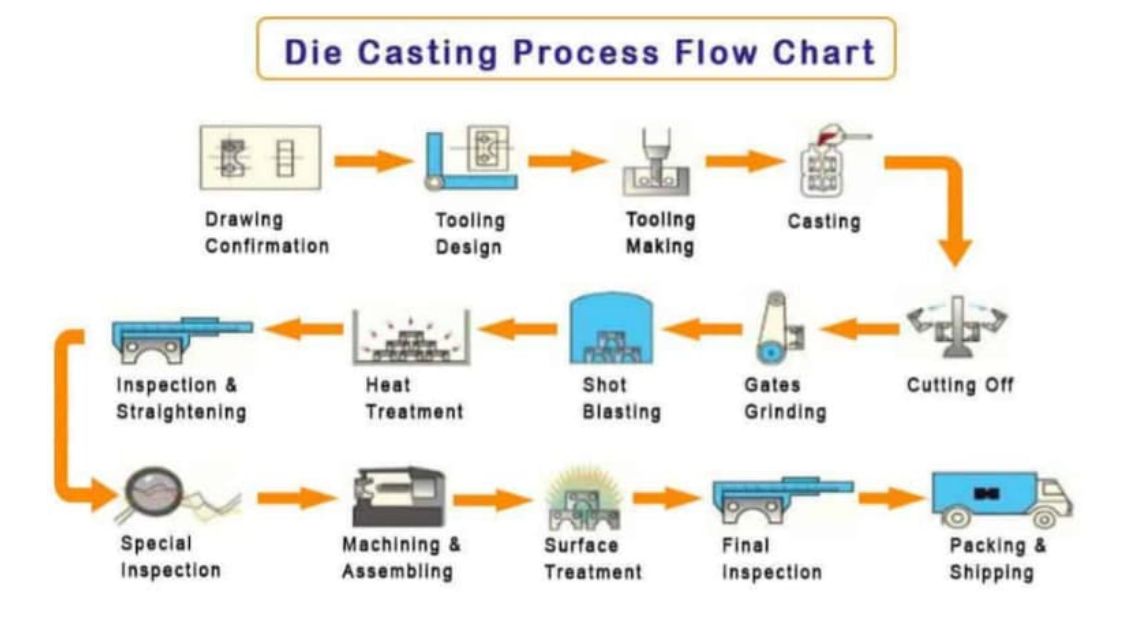

Ngawaphi amanyathelo enkqubo yokuphosa ukufa?

① Ukulungiselela iDie: I-Die, eyaziwa ngokuba ngumbumba, ilungiselelwe inkqubo yokuphosa.Idayi ineziqingatha ezibini, isiqingatha esisisigxina (isigqubuthelo sokufa) kunye nesiqingatha esisuswayo (i-ejector die), edala ubume obunqwenelekayo bemveliso yokugqibela.

②Ukunyibilikisa iMetal: Isinyithi esikhethiweyo esingenayo i-ferrous, njenge-aluminium, i-zinc, okanye i-magnesium, iyancibilika kwisithando somlilo kwiqondo lokushisa eliphezulu.Isinyithi esinyibilikisiweyo sifikelela kubushushu obufunwayo bokugalelwa.

③ Isitofu: Isinyithi esinyibilikisiweyo sitofwa kwidiyizi ngoxinzelelo oluphezulu.Ipiston okanye iplunger inyanzela isinyithi esinyibilikisiweyo ukuba singene kumngxuma wokufa ngokusebenzisa i-sprue, imbaleki, kunye nenkqubo yesango.Uxinzelelo lunceda ukugcwalisa isikhunta ngokupheleleyo kwaye uqinisekise ukuba umzobo ofunwayo ufezekiswa.

④Ukuqina: Nje ukuba isinyithi esinyibilikisiweyo sifakwe kwidiyethi, iphola ngokukhawuleza kwaye yomelele ngaphakathi kumngxunya wokufa.Inkqubo yokupholisa ilawulwa ngokucophelela ukuqinisekisa ukuba isinyithi siqina ngokufanayo kwaye singenasiphako.

⑤ Ukukhutshwa: Emva kokuba isinyithi siqinile kwaye sipholile ngokwaneleyo, iihafu zokufa ziyavulwa, kwaye ukuphosa, okwakwaziwa ngokuba yi-die casting, kukhutshwa kwi-cavity yokufa.Izikhonkwane zokukhupha okanye iipleyiti ze-ejector zinceda ukutyhala ukuphosa ngaphandle kwefa.

⑥Ukucheba kunye nokuQeda: Ukuphosa ukufa okukhutshiweyo kunokuba nemathiriyeli engaphezulu, eyaziwa ngokuba yi-flash, ejikeleze imiphetho yayo.Le mathiriyeli igqithileyo iyasikwa ukuze ifikelele kwimo yokugqibela efunekayo.Iinkqubo zokugqiba ezongezelelweyo ezinje ngomatshini, isanti, okanye ukupolishwa kunokwenziwa ukuze kucokiseke umphezulu kunye nokuchaneka komda kokusa.

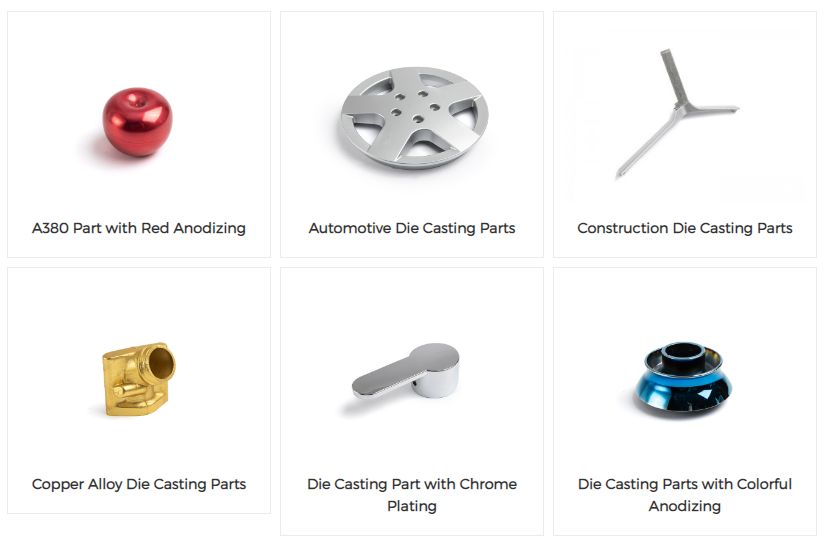

⑦ Emva koNyango: Ngokuxhomekeke kwiimfuno ezithile kunye nokusetyenziswa kwe-die casting, iinkqubo ezongezelelweyo emva konyango zingaqhutywa.Oku kunokubandakanya unyango lobushushu, ukugquma komhlaba, ukupeyinta, okanye naziphi na ezinye iinkqubo ezifunekayo zokugqiba ukunyusa iipropati okanye imbonakalo yokuphosa.

Ungayikhetha njani inkqubo yokuphosa ngokweyona meko?

Ukukhetha inkqubo efanelekileyo yokuphosa ukufa kuxhomekeke kwizinto ezininzi kunye neengqwalasela ezinxulumene neyona meko.Nanga amanye amanqaku aphambili ekufuneka uwaqwalasele xa ukhetha inkqubo yokuphosa ukufa:

Izinto:Chonga uhlobo lwentsimbi okanye ialloyi eza kusetyenziselwa ukugalela.Iintsimbi ezahlukeneyo zineempawu kunye neempawu ezahlukileyo, ezifana nobushushu obunyibilikayo, ubumanzi, kunye nesantya sokushwabana.Cinga ngeemfuno ezithile zenxalenye okanye imveliso, njengamandla, ubunzima, ukuxhathisa ukubola, kunye ne-thermal conductivity, kwaye ukhethe inkqubo yokuphosa i-die efanelekileyo kwizinto ezikhethiweyo.

Ukuntsonkotha kweCandelo:Vavanya ukuntsonkotha kwenxalenye okanye imveliso eza kwenziwa.Qinisekisa ukuba ineemilo ezintsonkothileyo, iindonga ezibhityileyo, ii-undercuts, okanye iimpawu ezintsonkothileyo zangaphakathi.Ezinye iinkqubo zokuphosa ukufa, ezifana ne-high-pressure die casting (HPDC) okanye i-multi-slide die casting, ifaneleka kangcono ukuvelisa iinxalenye ezinzima kunye nokunyamezela okuqinileyo, ngelixa ezinye zinokuthi zifaneleke ngakumbi kuyilo olulula.

Umthamo weMveliso:Qwalasela umthamo ofunekayo wemveliso.Iinkqubo zokuphosa i-Die zingahlelwa zibe yi-high-pressure die casting (HPDC) kwimveliso ephezulu yomthamo kunye ne-low-pressure die casting (LPDC) okanye i-gravity die casting for volumes ephantsi.I-HPDC ikholisa ukusebenza kakuhle ngakumbi kwaye ineendleko zokonga kwimveliso yomgangatho omkhulu, ngelixa i-LPDC kunye ne-gravity die casting zifaneleka ngcono imveliso emincinci eqhutywayo okanye iprototyping.

UkuGqiba komphezulu kunye nokuChaneka:Vavanya umphezulu ofunekayo wokugqiba kunye neemfuno zokuchaneka kobukhulu becala.Ezinye iinkqubo zokuphosa ukufa, ezinje ngokukhama okanye ukuphosa kufa kwevacuum, zinokubonelela ngokuphucuka komphezulu wokugqiba kunye nokunyamezelana okuthe kratya xa kuthelekiswa nokuphoswa koxinzelelo oluphezulu lwemveli.Ezi nkqubo zinokukhethwa kwiindawo ezifuna ukugudiseka okukhethekileyo komphezulu okanye imilinganiselo echanekileyo.

Izixhobo kunye neZixhobo:Vavanya ukufumaneka kwezixhobo kunye nezixhobo ezifunekayo kwinkqubo yokuphosa ukufa.Ezinye iinkqubo zinokufuna oomatshini abakhethekileyo, abanje ngoomatshini bokuphosa boxinzelelo oluphezulu okanye iinkqubo zokuphosa eziphantsi koxinzelelo.Qwalasela iindleko, ixesha lokukhokela, kunye nokuba nokwenzeka kokufumana okanye ukulungisa izixhobo eziyimfuneko kunye nezixhobo zenkqubo ekhethiweyo.

Iindleko kunye nokusebenza kakuhle:Vavanya ukusebenza kakuhle kweendleko kunye nokusebenza kakuhle kwenkqubo yokuphosa ukufa.Qwalasela izinto ezifana neendleko zempahla, iindleko zezixhobo, ixesha lomjikelo wemveliso, ukusetyenziswa kwamandla, kunye neemfuno zabasebenzi.Thelekisa iingenelo kunye nemida yeenkqubo ezahlukeneyo ukumisela eyona ndlela ingabizi kakhulu kwiimfuno ezithile zemveliso.

Ubungcali kunye namava:Thatha ingqalelo ubuchule kunye namava akhoyo kumbutho wakho okanye kubaboneleli be-die casting.Ezinye iinkqubo zinokufuna ulwazi olukhethekileyo, izakhono, kunye nokusekwa kwezixhobo.Vavanya amandla kunye namava eqela lakho okanye amaqabane anokubakho ukuze uqinisekise ukuphunyezwa ngempumelelo kwenkqubo ekhethiweyo yokuphosa.

Ngokuqwalasela ngenyameko le miba kunye nokubonisana neengcali kwintsimi, unokwenza isigqibo esinolwazi kwaye ukhethe eyona nkqubo ifanelekileyo yokuphosa ukufa kwimeko yakho ethile.

Wamkelekile kuXiamen Ruicheng umboneleli owomeleleyo ukuba uthethe naye, uya kufumana iingcebiso zobungcali!

Ixesha lokuposa: Feb-05-2024