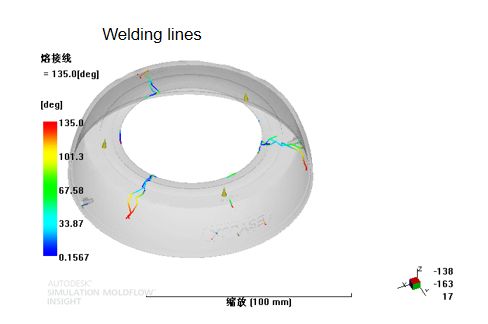

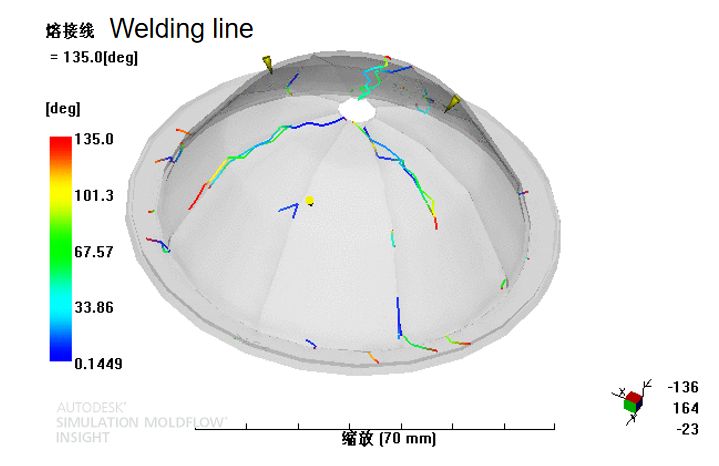

Yintoni umgca welding

Umgca we-welding ubizwa ngokuba yi-welding mark, uphawu lokuhamba.Kwinkqubo yokubumba inaliti, xa kusetyenziswa amasango amaninzi okanye imingxunya ikhona kumngxuma, okanye ukufakwa kunye neemveliso ezinotshintsho olukhulu kubukhulu bobukhulu, ukuhamba kweplastiki yokunyibilika kwenzeka kumngundo kwiindlela ezingaphezulu kwe-2.Xa iintambo ezimbini ezinyibilikayo zidibana, umgca we-welding uya kwenziwa kwinxalenye.Ukuthetha ngokuthe ngqo, phantse zonke iimveliso zinemigca ye-welding, kwaye kunzima ukuziphelisa ngokupheleleyo, kodwa ukuzinciphisa kuphela, okanye ukubenza bafudukele kwiindawo ezingabalulekanga.

(Umzekelo weWelding Line)

Izizathu zokubunjwa komgca we-welding

Ngethuba lenkqubo yokupholisa imicu emibini yeplastiki kwindawo yomgca we-welding, kuya kubakho umoya obanjwe phakathi kweentsimbi ezimbini zeplastiki.Umoya ovalelweyo uya kuthintela umphumo ojikelezayo weemolekyuli zepolymer kwaye ubangele ukuba amakhonkco eemolekyuli ahlukane.

Indlela yokunciphisa umgca we-welding

Uyilo lwemveliso kunye noyilo lokungunda

Ukuba inkangeleko kunye nokusebenza kwemveliso kubalulekile, umthengi kunye nomenzi wokubumba kufuneka basebenze kunye, ukunciphisa impembelelo yomgca we-welding kangangoko kunokwenzeka.Umthengi/umyili wemveliso kufuneka ancedise umenzi ekuqondeni umsebenzi ofanelekileyo wemveliso kunye nemiba ebalulekileyo yokuthambisa.Umyili wokubumba kufuneka emva koko aqwalasele umsebenzi wenxalenye kunye nendlela iplastiki igcwalisa ngayo okanye igeleza ngaphakathi kunye ne-mold ngexesha lesigaba soyilo lokubumba, ngokuqwalasela ulwazi olufanelekileyo olunikezwa ngumthengi, ukwandisa ukukhutshwa komoya kwindawo yomgca we-welding kunye nokunciphisa. umoya ovalelweyo.Kuphela xa umthengi kunye nomenzi we-mold basebenzisana ukuze baqonde imveliso kunye nokusebenza kunye kunokuqinisekisa ukuba indawo enoxinzelelo oluncinci lwe-welding line okanye ibonakale imbonakalo encinci ebalulekileyo.

Ukukhethwa kwezinto kunye nokusebenza

Izinto ezahlukeneyo zinamandla ahlukeneyo e-welding line.Ezinye izixhobo zoqhagamshelwano ezithambileyo zinobuntununtunu bokucheba kwaye iintambo zokuwelda zisenokwenzeka nokuba iqondo lobushushu elingaphambili aliphazanyiswa.Oku kunokufuna utshintsho lwezinto eziphathekayo ukusombulula ingxaki yomgca we-welding.

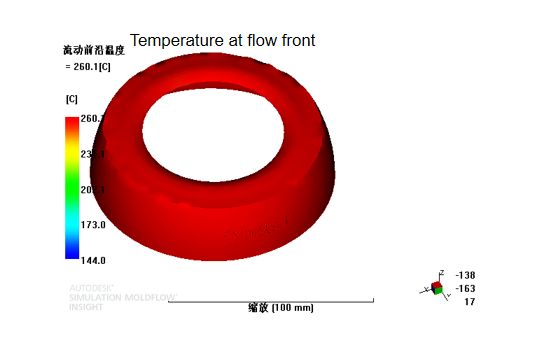

Ukuqwalaselwa kwenkqubo yokubumba isitofu

Iisitofu sokubumbainkqubo inokuchaphazela amandla kunye nesikhundla somgca we-welding.Ukuguquka kwenkqubo kwiqondo lokushisa kunye noxinzelelo kuya kuba nefuthe elithile kumgca we-welding.

Ukuba kunokwenzeka, qiniseka ukuba umgca we-welding wenziwa ngexesha lokuqala lokuzaliswa.Umgca we-welding owenziwe ngexesha lokupakisha kunye nezigaba zokubamba zihlala ziyingxaki.Ukuqulunqwa kwemigca ye-welding ngexesha lesigaba sokuzalisa kaninzi kunceda ukunyusa izinga lokuzaliswa, ngaloo ndlela ukunciphisa ixesha lokuzaliswa kunye nokwandisa izinga lokucheba.Oku kunciphisa i-viscosity ye-polymer ngexesha lokuzaliswa kwenkqubo, okukhokelela ekuphepheni okungcono kwamatyathanga e-molecular kunye nokuzaliswa lula.

Ngamanye amaxesha ukwandisa ixesha lokupakisha okanye ukubamba uxinzelelo kuya kunceda.Ukuba ukubonakala kungumba, isantya sokutofa esisezantsi sinokunceda, kodwa ngokuqhelekileyo ubushushu obuphezulu bokungunda buya kunika iziphumo ezingcono.Ukukhutshwa kwevacuum sisixhobo esinamandla esinokuba luncedo kakhulu ekuncedeni ngenkangeleko kunye nemicimbi yamandla.

Ngokungakumbiisitofu sokubumbaulwazi, nceda uzive ukhululekile ukubaQhagamshelana nathi.

Ixesha lokuposa: Dec-01-2022