Ulungisa ukhetho lwemathiriyeli lubalulekile ekudaleni iiprototypes zesiko kunye namalungu anokusebenza okufunwayo koomatshini, ukusebenza, kunye nobuhle.E-Xiamen Richeng, sinikezela ngolwazi olusisiseko lwezinto zokushicilela ze-3D kwaye sikuncede ukhethe izinto ezifanelekileyo kwinxalenye yakho yokugqibela.

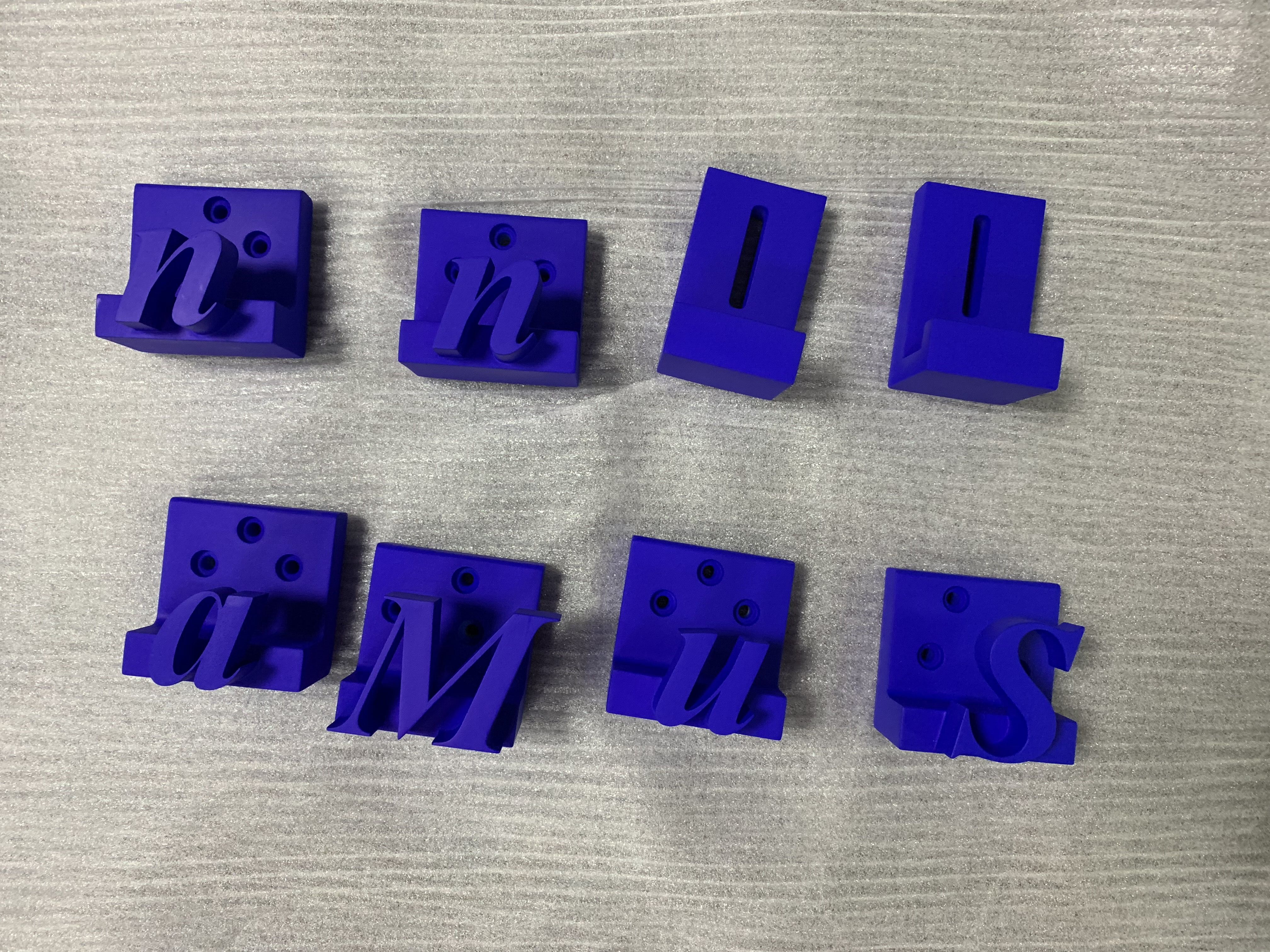

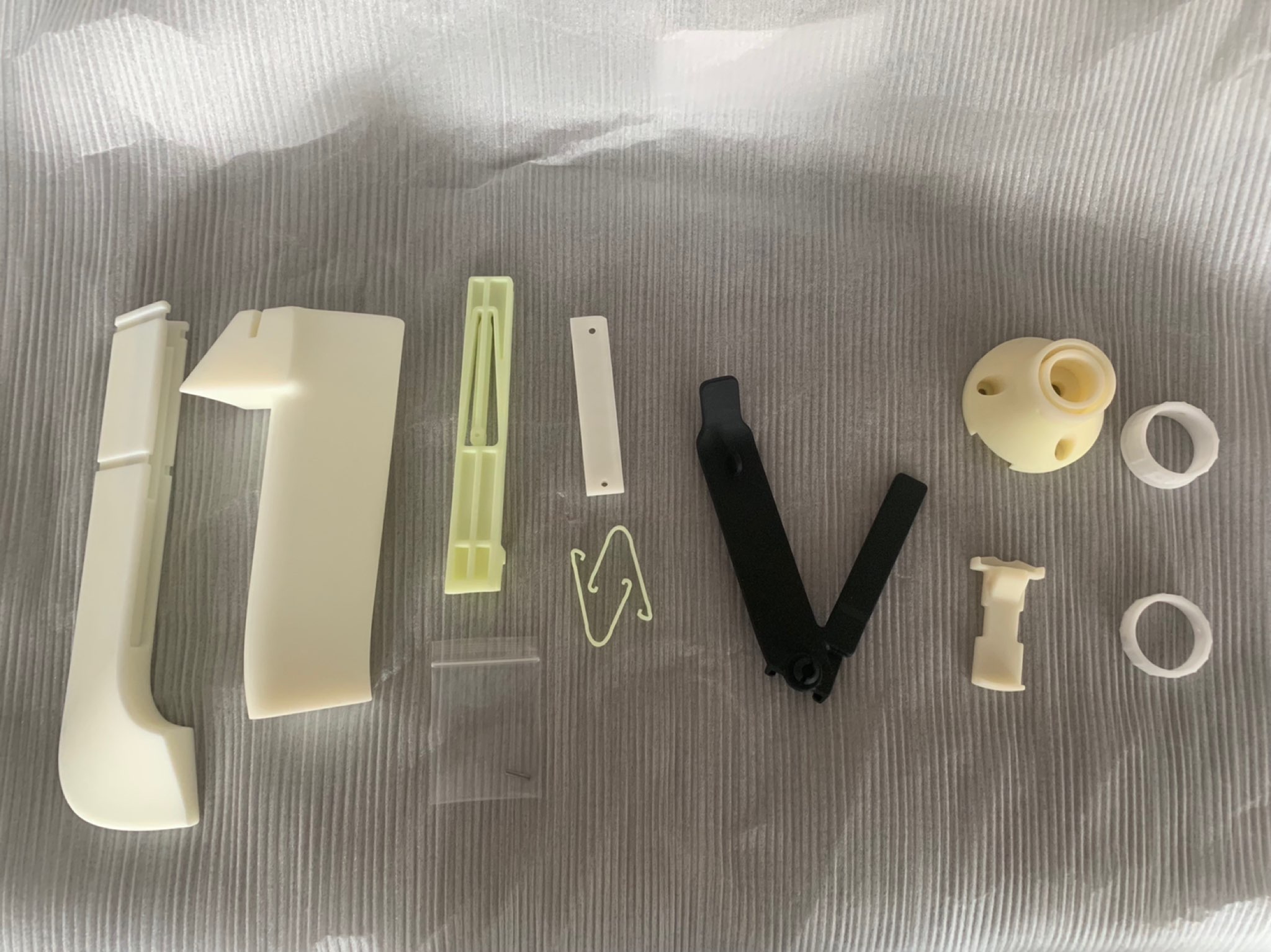

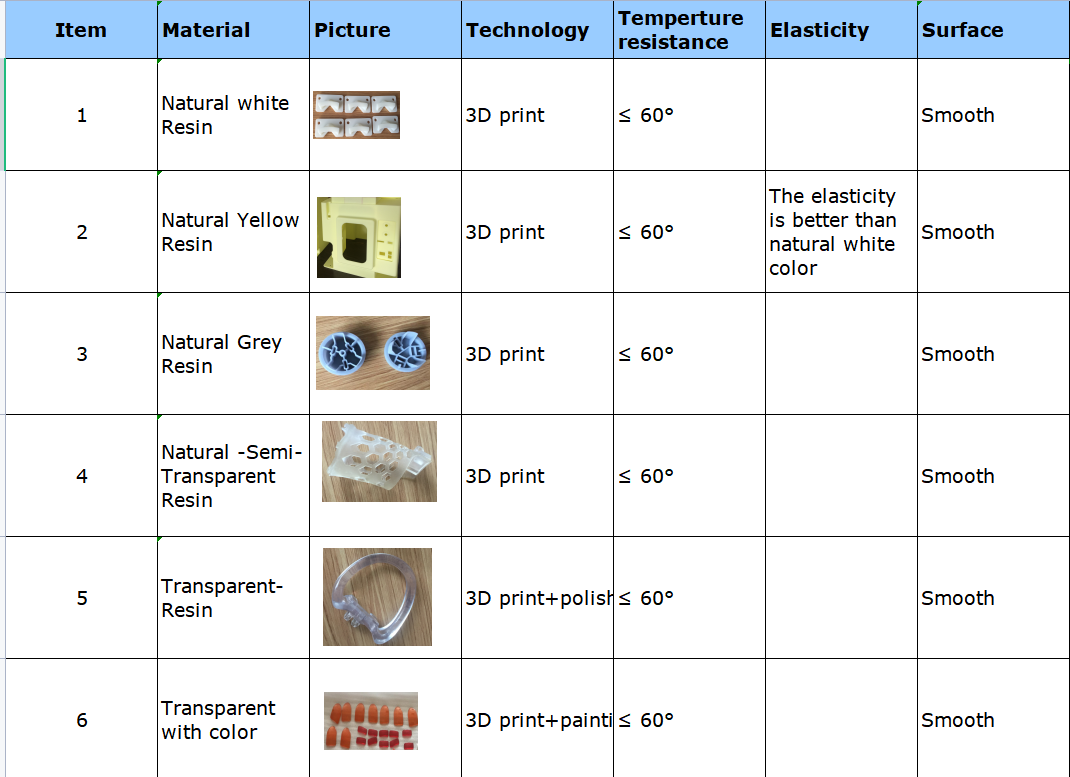

SLA

I-Stereolithography (SLA)yitekhnoloji yoshicilelo ye-3D esebenzisa i-photosensitive resin kunye nelaser ukudala ukuchaneka okuphezulu, iindawo ezineenkcukacha.Inkqubo ibandakanya ukuphilisa umaleko we-resin engamanzi kunye ne-laser beam, eqinisa i-resin kwaye ibambelele kuluhlu lwangaphambili.Iqonga lokwakha liyathotywa njengoko umaleko ngamnye uphiliswa de yonke inxalenye igqitywe.

Izinto eziluncedo:

Kwiimodeli zengqikelelo, iiprototypes, kunye noyilo oluntsokothileyo, i-SLA inokuvelisa iinxalenye ezinejiyometri entsonkothileyo kunye nokugqiba okugqwesileyo komphezulu xa kuthelekiswa nezinye iinkqubo zokuvelisa ezongezelelweyo.Iindleko ziyakhuphisana.

Izinto ezingeloncedo:

Amandla eenxalenye zeprototype asenokungabi mahle njengalawo enziwe ngeresin yebakala lobunjineli, ke iinxalenye ezenziwe nge-SLA zinosetyenziso olulinganiselweyo kuvavanyo olusebenzayo.Ethambileyo, njengoko uyilo olufuna amandla ludla ngokwenziwa nge-CNC.I-CNC inezinto ezininzi zokukhetha kuzo kwaye inokukhetha izixhobo ezahlukeneyo ngokusekelwe kwiimfuno zamandla.

Izinto ezisetyenziswa ngokuqhelekileyo ziquka:

Godart® 8001 /Godart ®8228 /Godart® 8111X

Eyona projekthisenze ireferensi

SLS

I-Selective Laser Sintering (SLS) yitekhnoloji yoshicilelo ye-3D esebenzisa i-laser ephezulu yamandla ukunyibilika kunye nokudibanisa izinto ezinomgubo, ezifana neyiloni okanye i-polyamide, ibe yinto eqinile.Inkqubo ibandakanya ukusabalalisa umaleko obhityileyo wezinto ezinomgubo phezu kweqonga lokwakha kwaye emva koko usebenzisa i-laser ukukhetha i-sinter (i-fuse) umgubo kunye kwimilo yenxalenye efunekayo.Iqonga lokwakha liyathotywa njengoko umaleko ngamnye usenziwa sintered, kwaye inkqubo iphinda iphindwe ide iphele yonke inxalenye.Itekhnoloji ye-SLS ifanelekile ukuvelisa iijometri ezintsonkothileyo kunye neendawo ezisebenzayo ezinamandla amakhulu.Isetyenziswa kakhulu kumashishini ahlukeneyo, kubandakanya i-aerospace, izithuthi, kunye nezonyango, ukwenza iprototyping, izixhobo zokusebenza, kunye neendawo zokusetyenziswa kokuphela.

Izinto eziluncedo:

I-nylon ye-SLS inamandla angcono xa kuthelekiswa ne-SLA kwaye inokucubungula izakhiwo ezinzima.

Izinto ezingeloncedo:

Amalungu ane-granular okanye i-sandy texture, kwaye umphezulu unzima, ufanelekile kwiimveliso ezineemfuno eziphantsi kunye nokuchaneka.

Izinto ezisetyenziswa ngokuqhelekileyo ziquka:

PA12

Eyona projekthisenze ireferensi

I-SLM

I-Selective Laser Melting (SLM) yitekhnoloji yoshicilelo ye-3D esebenzisa i-laser ephezulu yamandla ukunyibilika kunye nokudibanisa i-powders yesinyithi ukwenza iindawo eziqinileyo.

Izinto eziluncedo:

Iintsimbi ezininzi ziyafumaneka ukuze zikhethwe kwaye zinokufikelela kwiimilo ezinzima okanye iimpawu zangaphakathi.Ixesha elifutshane lokuvelisa.

Izinto ezingeloncedo:

Xa kuthelekiswa ne-SLA / SLS, ixabiso liphezulu, umphezulu unzima, kwaye ininzi ye-post-processing iyadingeka, kwaye ukuchaneka akukona phezulu.

Izinto ezisetyenziswa ngokuqhelekileyo ziquka:

A1Si10Mg / 316L /1.2709 / TC4 /GH4169

Eyona projekthisenze ireferensi

Imibuzo engakumbi kwitekhnoloji yoshicilelo ye-3D, nceda uzive ukhululekile ukuqhagamshelana nathi.

Ixesha lokuposa: Jun-19-2023