Ukubumba irabha yinkqubo yokuvelisa ebandakanya ukubumba izinto zerabha kwiifom ezithile kunye nemilinganiselo.Le nkqubo isetyenziswa ngokuqhelekileyo ukuvelisa uluhlu olubanzi lweemveliso zerabha, kubandakanywa izitywina, i-gaskets, i-O-rings, kunye namacandelo ahlukeneyo oshishino.

Kukho iindlela ezininzi zokubumba irabha, kubandakanywa ukubumba ucinezelo, ukubumba ukudluliselwa, ukubumba inaliti, kunye nokubumba inaliti yolwelo.Indlela nganye ineenzuzo zayo kwaye ifanelekile kwiintlobo ezahlukeneyo zeemveliso zerabha.

Ukubumba iRubber yinkqubo eguquguqukayo evumela ukuveliswa kweemilo ezinzima kunye noyilo oluyinkimbinkimbi.Isetyenziswa kakhulu kumashishini afana neemoto, i-aerospace, i-electronics, kunye nezixhobo zonyango.

Ngokubanzi, ukubumba irabha kudlala indima ebalulekileyo ekuvelisweni kweemveliso ezahlukeneyo zerabha, ukubonelela ngendlela engabizi kakhulu nesebenzayo yokuvelisa amacandelo akumgangatho ophezulu.

Namhlanje siza kunikela ingqalelo ukukubonisa malunga nobuchwepheshe bokubumba irabha ukusuka kuhlobo lwetekhnoloji, inzuzo yokubumba irabha kunye nokusetyenziswa.

YINTONI UKUBUMBA IRABHA?

Ukubumba irabha yinkqubo yokuvelisa esetyenziselwa ukuguqula irabha enganyangekiyo ibe yimveliso esebenzisekayo.Oku kufezwa ngeenkqubo ezahlukeneyo, kubandakanywa ukufudumeza kunye nokuhlaziya irabha kwindawo yentsimbi.Iindidi ezintathu eziphambili zokubumba kukubumba inaliti, ukubunjwa koxinzelelo, kunye nokudlulisa ukubumba.

Iintlobo ezintathu zeteknoloji yokubumba irabha

RubberUkubunjwa kwe-Inejection

Ukubunjwa kwenaliti yerabha kufezekiswa ngokutofa irabha enganyangekiyo kumngundo.Irabha ihleli ekubunjeni kangangexesha elithile ide ibe sengozini yokumila kokugqibela.Nangona isitofu sokubumba luhlobo lokubumba irabha, lunokusetyenziswa kwizinto ezininzi ezahlukeneyo, njengentsimbi kunye neglasi.

Ukubumba iRubber Compression

Ukubumba ukunyanzeliswa kwerabha kufezekiswa ngokubeka imilo esele yenziwe ngaphambili yerabha enganyangwanga kumngxunya wokungunda obushushu emva koko usebenzisa uxinzelelo lwehydraulic ukuyitywina.Irabha igcinwa kumngxuma oshushu de ibunjwe ukuze ibe nokumila kwayo kokugqibela.

Ukubunjwa kweRubber Transfer

Ukubunjwa kokudluliselwa kwerabha kufezekiswa ngokulayisha inani elithile lerabha engabonakaliyo kwitanki yokudlulisa.I-punch iyavalwa kwaye i-preform ityhalelwe kwi-cavity yendawo ngokusebenzisa umgijimi kunye nenkqubo yesango.Irabha igcinwe kumngxuma oshushu kangangexesha elithile ukuyinyanga ibe nokumila kwayo.

Umlingo wokuBumba iRubber

Ukubumba irabha yinkqubo eguquguqukayo nesebenzayo ekuvumela ukuba uphindaphinde ngokulula iinkcukacha ezintsonkothileyo kwaye wenze iimilo ezintsonkothileyo.Nokuba ungumyili wemveliso, igcisa, okanye injineli, ukuqonda iinuances zokubumba irabha kunokunika iiprojekthi zakho ukomelela okukhulu.

Ikopi echanekileyo

Enye yezinto ezibalaseleyo zokubumba irabha kukukwazi ukuvelisa ezona nkcukacha zincinci.Olu hlobo lokuveliswa kwakhona luxabiseke kakhulu kumashishini apho uyilo oluntsonkothileyo lubalulekile.Imizekelo ibandakanya ukwenziwa kwezacholo, ukwenziwa kwemifanekiso emincinci, okanye ukubuyisela amazinyo.

Ukuba bhetyebhetye kwezinto

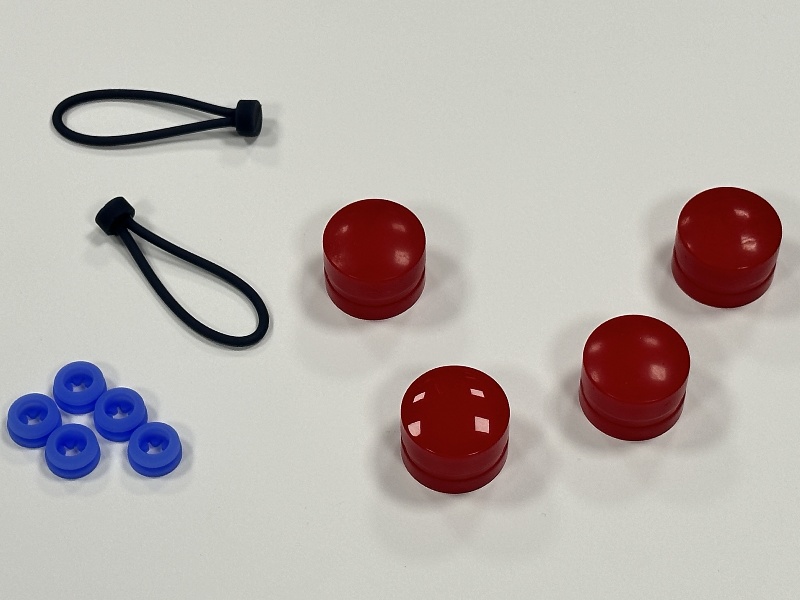

Imibumbo yerabha inokwenziwa ngezinto ezahlukeneyo, kubandakanya i-resin, iplastiki, kunye nokubaizinto zokutya-gradenjengeminqwazi yokutywina.Oku kuguquguquka kuvula ihlabathi lamathuba okulinga kunye nokuvelisa izinto ezintsha kwiinkalo ezahlukeneyo.

Ukusebenza kweendleko

Ubuchwephesha obuphezulu bokubumba irabha bubonelela ngezisombululo ezingabizi kakhulu kwimveliso encinci kunye nenkulu.Ukukwazi ukwenza i-molds echanekileyo kunciphisa inkunkuma yezinto eziphathekayo, ukugcina imali ekuhambeni kwexesha.

Yonga ixesha

Isantya seenkqubo zokubumba irabha, njengokubumba inaliti, kunokunciphisa kakhulu amaxesha okuvelisa.Oku kuthetha ukuba iiprojekthi zakho zijika ngokukhawuleza kwaye unokuhlangabezana nemihla ebekiweyo.

Inkululeko yoyilo

Itekhnoloji yokubumba irabha ikunika inkululeko yokulinga uyilo oluntsonkothileyo olunokuba nzima ukufikelela ngezinye iindlela.Oku kuguquguquka kokudala kukuvumela ukuba utyhale imida yeeprojekthi zakho.

Ukubumba irabha yinkqubo eguquguqukayo efumana isicelo kumashishini ahlukeneyo.Ezinye izicelo eziqhelekileyo zokubumba irabha ziquka:

1. Ushishino lweemoto: Ukubumba iRubber kusetyenziselwa ukuvelisa uluhlu olubanzi lwamacandelo eemoto ezifana nezitywina, i-gaskets, i-O-rings, i-hoses, kunye ne-vibration dampeners.

2. Ishishini lezonyango: Ukubumba irabha kusetyenziselwa ukuvelisa izixhobo zonyango, ezifana nezitywina, i-gaskets, kunye namacandelo erabha aqhelekileyo kwizixhobo zonyango.

3. Ishishini lombane: Ukubumba irabha kusetyenziselwa ukuvelisa izigqubuthelo zokukhusela, iigrommets, kunye nezitywina zezixhobo zombane kunye namalungu.

4. Ishishini lempahla yabathengi: Ukubumba irabha kusetyenziselwa ukuvelisa iintlobo ngeentlobo zeemveliso zabathengi, kubandakanywa irabha yokubamba, itywina, kunye neegaskets zezixhobo zendlu kunye nezixhobo.

5. Ishishini lempahla yezemidlalo: Ukubumba irabha kusetyenziselwa ukuvelisa amacandelo eempahla zemidlalo, ezifana nokubamba, izitywina, kunye nokukhusela izixhobo.

6. Izinto zokudlala: Amanani entshukumo, ukubumba irabha kuvumela ukuveliswa kwamanani kunye nabalinganiswa abaguquguqukayo kunye nesigxina serabha.

Le yimizekelo nje embalwa yemisebenzi emininzi yokubumba irabha kumashishini ahlukeneyo.Inkqubo ixabiswa ngokukwazi kwayo ukuvelisa amacandelo erabha eyenzelwe ngokwezifiso ngokuchaneka okuphezulu kunye nokuqina.

Isishwankathelo

Eli nqaku lihlalutya iimpawu zokubumba i-rubber, , kunye neendlela zokubumba, eziza kunceda ngethemba iprojekthi yakho yezinto zerabha.

Eli nqaku likhankanya uhlobo lwetekhnoloji yokuBumba iRubber kunye nezibonelelo zayo, ezifuna amava aphezulu ababoneleli bokubumba isitofu kunye nababoneleli bemveliso yokubumba inaliti.

Ukuba uneprojekthi ebandakanya ezi nkqubo zimbini, kuyacetyiswa ukuba uqinisekise ukuba umzi-mveliso we-injection mold kunye ne-injection yokubumba imveliso inamava ekwenzeni iimveliso ezifanayo ukuqinisekisa ukuphunyezwa okugudileyo kweprojekthi okanye unako.Qhagamshelana nathi, amaqela ethu ochwephesha aya kuphendula imibuzo yakho.

Ixesha lokuposa: May-13-2024