Namhlanje sixoxa nge-electro-spark deposition's application kwialloys zetsimbi, kwangaxeshanye siza kugxila kobu buchwepheshe silungisa njani ukubumba kwisixhobo sokubumba inaliti kunye nokubunjwa kokuphosa.

Yintoni i-Electro-Spark Deposition?

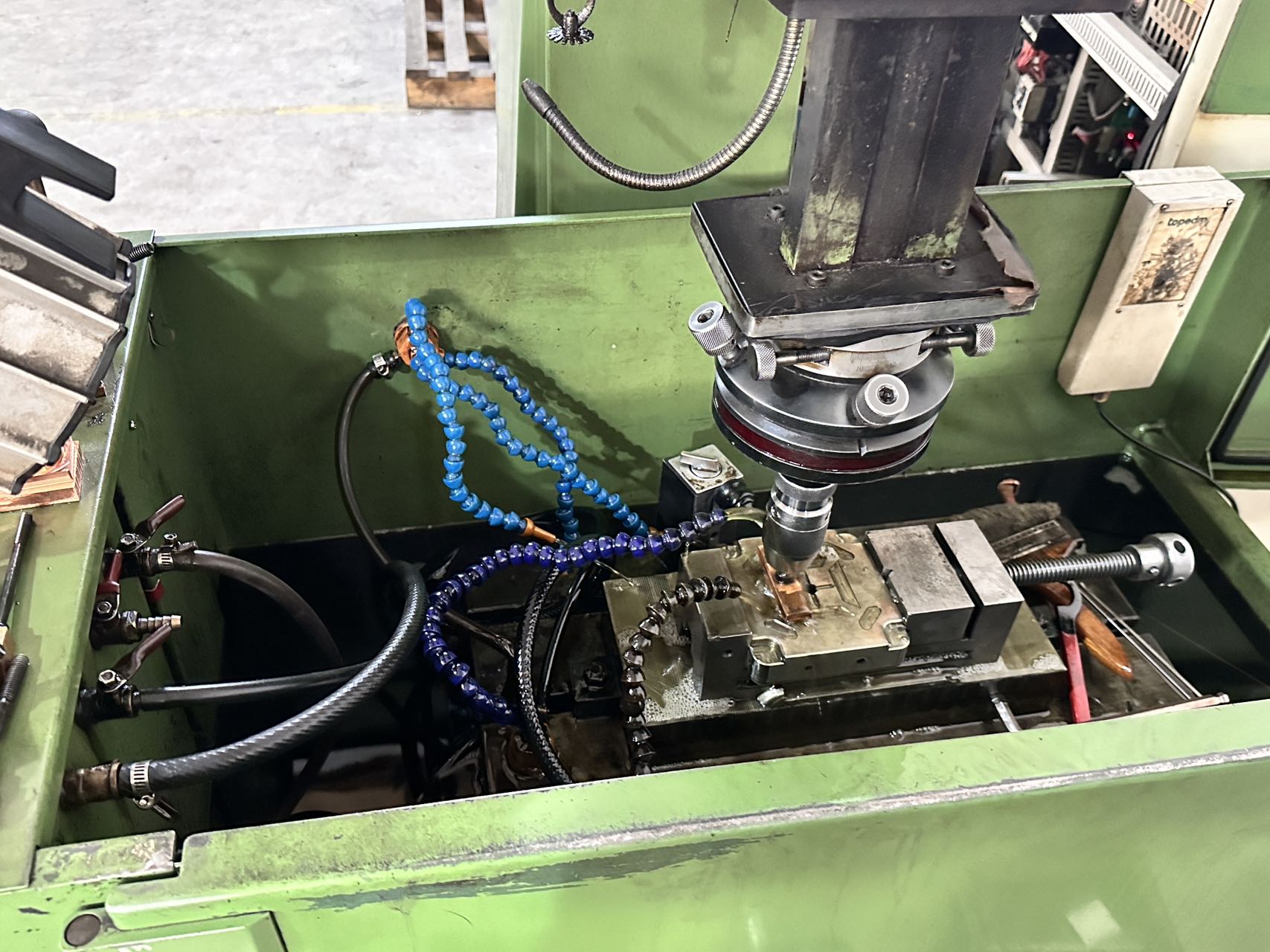

Unyango lwe-Electro-spark, eyaziwa ngokuba yi-Electro-discharge machining (EDM), yinkqubo ekhethekileyo yokuvelisa ebandakanya ukusetyenziswa kokukhutshwa kombane ukubumba kunye nokuguqula umphezulu weendawo zetsimbi.

Ngexesha lonyango lwe-Electro-spark, ukukhutshwa kombane kuveliswa phakathi kwe-electrode kunye ne-workpiece, ngokuqhelekileyo yenziwe ngezinto eziphathekayo ezifana nentsimbi okanye i-alloys.Inkqubo iqala ngokubeka i-electrode, kaninzi ngendlela yesixhobo esincinci, esibunjiweyo, ngokusondeleyo kwi-workpiece.

Xa i-voltage isetyenziswe phakathi kwe-electrode kunye ne-workpiece, uchungechunge lokukhutshwa kombane ngokukhawuleza kwenzeka.Oku kukhutshwa kudala ubushushu obukhulu, kunyibilika iindawo ezincinci zomphezulu womsebenzi.Isinyithi esinyibilikisiweyo sicinywa ngokukhawuleza lulwelo lwe-dielectric, yenze ukuba iqine kwaye yenze ama-craters amancinci okanye ukungena.

I-ESD isetyenziswe kwi-alloys zetsimbi

Xa amandla e-capacitor ekhutshwa, umbane othe ngqo udala i-arc ye-plasma ephezulu yobushushu phakathi kwe-electrode tip kunye ne-workpiece ye-alloy metal.Olu luhlu luphezulu lobushushu luphakathi kwe8000 kunye ne25000°C.I-arc ye-plasma i-ionize i-anode kwaye idlulisela ngokukhawuleza into etyhidiweyo kwi-workpiece.

Le anode ye-ionizing idluliselwa kwi-substrate nge-pulses emfutshane.I-arc yobushushu obuphezulu iqukethe iincinci ze-anode, umlambo wokushisa (ijet eshushu), kunye ne-plasma eyenziwe ngokubola kweegesi kunye ne-athomu esebenzayo ye-nitrogen, i-oksijini kunye nekhabhoni.Uninzi lobushushu buthwalwa ziijethi ezishushu kunye neplasma.

Ngenxa yokuba ii-pulses zifutshane, ukuhanjiswa kobushushu ngejethi ye-thermal kunye nezinye iigesi zincinci, kwaye ukuhanjiswa kobushushu kuphela kwi-substrate yi-particle encinci ye-anode efakwe kwi-substrate.Ngoko ke, ezi pulses zidlulisela ubushushu obuncinane kwi-substrate ngaphandle kokutshintsha i-microstructure ye-substrate.Le ndlela inenzuzo ngakumbi kunenkqubo yokudityaniswa kwe-welding edla ngokusetyenziswa ukulungisa ingxubevange eneempawu zezowuni ezichatshazelwe bubushushu (umzekelo, ubunzima obuphantsi, ubulukhuni obuphezulu, ukuqhekeka kwe-liquefaction).

Ukongeza, inkqubo inceda ukudala ibhondi eyomeleleyo ye-metallurgical phakathi kwe-substrate kunye nokwaleka.I-Microalloying phakathi kwe-electrode iyancibilika kwaye i-substrate iqala ukubunjwa kweplasma ngokuchithwa komoya, i-carbonates, i-carbides kunye ne-nitrides.

Iingenelo

I-1.Ukuchaneka nokuchaneka: Unyango lwe-Electro-spark luvumela ukubunjwa okuchanekileyo kunye nokuchanekileyo kweenkcukacha eziyinkimbinkimbi kunye neengqungquthela ezinzima kwiindawo zetsimbi.Ukukhutshwa kombane okulawulwayo kuphazamisa izinto ngendlela elawulwayo, eyenza ukudala iimpawu ezichanekileyo ezifana nemingxuma emincinci, i-slots, okanye i-indentations ngokuchaneka komgangatho ophezulu.

I-2.Ukugcinwa kweMfezeko yezinto eziphathekayo: Enye yeenzuzo ezibalulekileyo zonyango lwe-Electro-spark kukukwazi ukugcina ukuqina kunye nokunyaniseka komsebenzisi.Ngokungafaniyo neendlela zemveli zomatshini ezinokuvelisa ubushushu obugqithisileyo kwaye zenze utshintsho olungafunekiyo kwizinto eziphathekayo, unyango lwe-Electro-spark lunciphisa iindawo ezichatshazelwe ngubushushu kwaye lugcine ubulukhuni besixhobo sokusebenza kunye nokuthembeka kwesakhiwo.

3.Iijometri eziNxibelele: Unyango lwe-Electro-spark luvumela ukwenziwa kweejiyometri ezintsonkothileyo ezinokuba ngumngeni okanye zingenzeki ukufikelela ngeendlela eziqhelekileyo zomatshini.Ikhono layo lokubumba iimpawu ezintsonkothileyo livumela ukuveliswa kokubumba, ukufa, okanye amanye amacandelo aneekhonto ezizodwa kunye neenkcukacha eziyinkimbinkimbi, ukwandisa amathuba oyilo.

I-4.Ayikho i-Tool Wear: Ngokungafaniyo neendlela zemveli ze-machining ezibandakanya ukusika okanye i-abrasion, unyango lwe-Electro-spark alubandakanyi ukudibanisa ngokuthe ngqo phakathi kwesixhobo kunye ne-workpiece.Ngenxa yoko, kukho ukunxitywa kwesixhobo esincinci, okukhokelela kubomi obude besixhobo kunye nokuncipha kweendleko zokulondolozwa.

Isishwankathelo

Eli nqaku ikakhulu lizisa inkqubo ye-EDM kwinkqubo yokwenza isikhunta, kungekhona nje ukwazisa ukuhamba kwayo kwenkqubo, kodwa iphinde ingenise iingenelo eziphambili zale nkqubo.Ngevidiyo engentla, ndiyathemba ukuba unokuqonda inkqubo ngokucacileyo.Ukuba uneminye imibuzo, nceda uzive ukhululekileQhagamshelana nathi.

Ixesha lokuposa: Jun-07-2024