Iprototyping ye-CNC lukhetho oluhle kakhulu kuba yenza ukuba ukuveliswa kweeprototypes ezincinci ngexesha elifutshane xa kuthelekiswa nezinye iindlela.

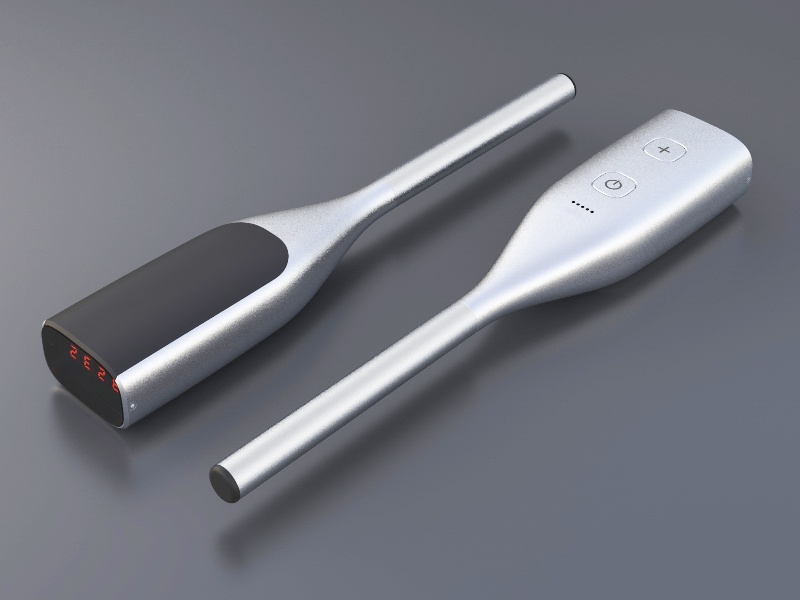

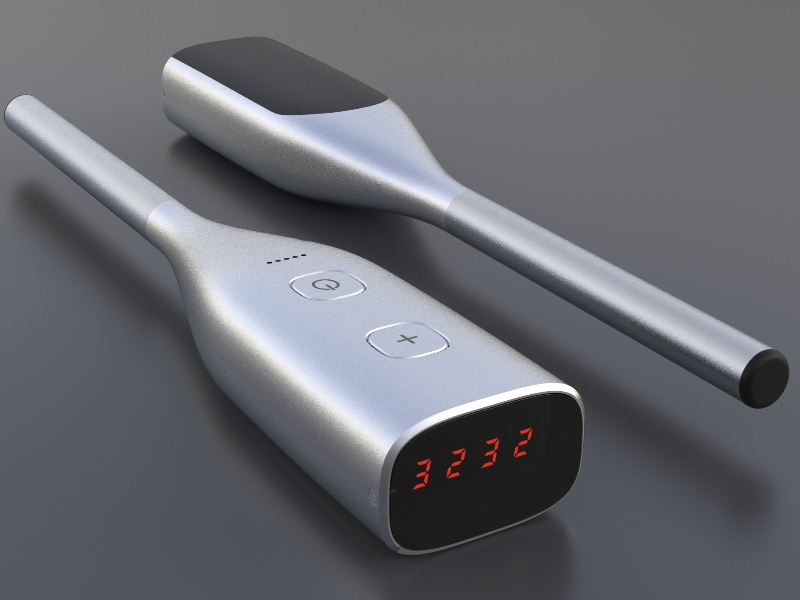

Iindidi ezahlukeneyo zeeprototypes zinokuveliswa ngokulula ngeCNC prototyping.Ngokomzekelo, i-mockup yembonakalo inokudlulisa ulwazi olubonakalayo malunga nendlela inxalenye yokugqibela eya kujongeka ngayo okanye iziphathe ngayo.Nangona kunjalo, iiprototypes ezisebenzayo zifuna ukunyamezela okuphezulu kunye nokuhlawula ingqalelo ngakumbi kwisakhiwo kunye nokuzinza kwemveliso.

Eli nqaku liza kwazisa usetyenziso lweeprototypes zomatshini we-CNC kunye nezinto eziluncedo kunye nezibi.Nceda uqhubeke ufunda!

CNCMhayi

Ukusetyenziswa kweCNC

Phantse kuwo onke amasimi achanekileyo, i-CNC prototype machining isetyenziswa ngokubanzi.Kuninzi lwala mashishini, kukho imfuneko yeprototype esebenzayo, okanye ubuncinane inguqulelo ebonisa indlela imveliso yokwenene isebenza ngayo.CNC machining of prototypes lolona khetho lufanelekileyo.

CNCMhayi

Ukwenziwa kwamalungu omatshini kunye nokwenza uMngundo

Nangona iimfuno ezichanekileyo zemveliso yokugqibela zisenokungafuneki ukwenziwa kwe-CNC, kubaluleke kakhulu ukuveliswa kwesikhunta, ngakumbi ezo zineemilo ezintsonkothileyo zangaphakathi kunye neegophe.Umatshini we-CNC ume njengeyona ndlela iphambili kwimveliso yokungunda.Ngelixa isixhobo sentsimbi kunye nentsimbi engatyiwa zezona zinto zisetyenziswa rhoqo ukwenza umngundo, ialuminiyam nayo iyasetyenziswa ngamaxesha athile.Nangona i-aluminiyam ayinako ixesha elide njengentsimbi xa iphantsi kobunzima bokubumba inaliti, isebenza njengenye indlela engabizi kakhulu yokuvelisa iibhetshi zamalungu abunjiweyo enaliti.

Iimolds zentsimbi ephosiweyo kufuneka zikwazi ukugcina ubungakanani bazo obuchanekileyo kunye neekhonto zangaphakathi ngaphezulu kwamawaka okanye izigidi zemijikelo yokubumba inaliti, kunye nabo bonke ubushushu kunye noxinzelelo olunxulumene nabo.CNC machining yenza kube lula umatshini ezi ntsimbi ukuya tolerances ezifunekayo.

Mechanical inxalenye

Ukwenziwa kwezixhobo zonyango

Inkalo yezonyango iqhubela phambili ngokukhawuleza, nto leyo enyanzelisa ukuvela kwezixhobo ezintsha.Nangona kunjalo, kwiimeko ezininzi, amashishini ezonyango afuna umbono weprototype.Oku kuqinisekisa ukuba imveliso inokuzalisekisa ngokunyanisekileyo injongo yayo.Ukuthathela ingqalelo ukubaluleka kobomi bomntu, kukho indawo encinci yeempazamo, efuna ukuba iprototype ibe yikopi echanekileyo kunye nokusebenza ngokupheleleyo kwemveliso yokugqibela.

Ukudalwa kwesi sixhobo kuwela phantsi koxanduva lweprototype ye-CNC.Ezi ziquka amathambo, iindawo ezivaliweyo zokhuseleko, ukufakelwa, oomatshini beMRI kunye nezixhobo zophando, phakathi kwabanye.

Iteknoloji yokuvelisa i-CNC yonyango inokudala ngokukhawuleza izixhobo zonyango.Ngokuxhomekeke kubunzima bayo, unokwenza inxalenye epheleleyo kwiiyure nje ezimbalwa.Kwiimeko ezingxamisekileyo zonyango, xa iintlobo zamalungu okanye amacandelo afunekayo kunzima ukuqikelela, ukuveliswa kwe-CNC kwenza ukuhanjiswa ngokukhawuleza kwamacandelo akumgangatho ophezulu kwimiyinge eyahlukeneyo.

Izixhobo zonyango

Ukwenziwa kwezixhobo zombane

Umatshini we-CNC wonwabela ukuthandwa ngokubanzi njengobuchule bokwenza obuthandwayo kwicandelo le-elektroniki.Le ndlela ikhethekileyo isebenzisa izixhobo zekhompyutha ukwenza amacandelo ngokuchaneka okukhulu.Amashishini amaninzi asebenzisa oomatshini be-CNC ukwenza izinto zombane, kubandakanya iibhodi zesekethe eziprintiweyo kunye nezinzwa.

Ukugcina ukuhambelana komgangatho kwinkqubo yokuvelisa i-electronics kubalulekile njengoko kunceda ukuqinisekisa ukuba imveliso ihlangabezana nokulindela kwabathengi kunye neemfuno.Oku kukwanceda ekunciphiseni ukubakho kweziphene kunye nokusebenza ngokutsha, ukonga ixesha kunye nemali.

Ukwamkela itekhnoloji yomatshini weCNC kuya kuvumela iinkampani ze-elektroniki ukuba zivelise iimveliso ezichanekileyo, okukhokelela kwiimveliso ezikumgangatho ophezulu kunye nokusebenza okuthembekileyo.

Amalungu e-elektroniki

Funda nzulu

Ukuba ukulungele ukuzisa CNC machine ubuchule kwivenkile yakho yokwenza umngundo?NdiyacelaQhagamshelana nathi.

Ixesha lokuposa: Mar-08-2024