Isitofu sokungundazixhobo zenkqubo eziphambili zemveliso yemveliso, ukusetyenziswa kwesikhunta ukuvelisa iinxalenye zeplastiki, kunye noluhlu lweenzuzo ezifana nokubonelela ngokufanelekileyo kwemveliso, kulula ukuqinisekisa umgangatho, iindleko eziphantsi zemveliso, ii-injection molds zisetyenziswa ngokubanzi kwimveliso yemveliso.Njengeyona nkqubo ibalulekileyo yokubumba i-injection, umgangatho wokubumba kwayo uchaphazela ngokuthe ngqo umgangatho weemveliso, ngelixa iindleko zokuvelisa i-molds zithatha umlinganiselo omkhulu weendleko zophuhliso lwamashishini.Ngoko ke phucula ubomi benkonzo/ubomi bokudutyulwa benaliti yokubumba ukunciphisa iindleko zeemveliso zeplastiki, ukuphucula imveliso yeshishini kunye nokhuphiswano kunempembelelo ebalulekileyo.

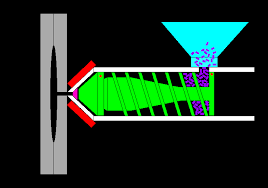

Inkqubo yokubumba inaliti yeplastiki ubukhulu becala zizinto zeplastiki ekrwada kumbhobho womatshini wokutofa emva kokufudumeza iplastiki, kumatshini wokutofa ukuqhubela phambili, emva kokuba iplastiki ifikelele kubushushu obuthile, ngoxinzelelo oluthile kunye nesantya ngokusebenzisa umbhobho womatshini wokutofa kwindawo yokungunda, kwaye emva koko isikhunta emva koxinzelelo, imveliso yokupholisa kwaye uvule isikhunta kwaye ufumane iinxalenye zeplastiki.

Ngexesha lenkqubo yokubumba, umphezulu wokubumba kufuneka uthwale uxinzelelo xa ukubunjwa kuvaliwe, uxinzelelo lweplastiki lunyibilika kwindawo yokubumba kunye namandla okutsala xa kuvulwa ukubumba, apho uxinzelelo lweplastiki lunyibilika. emngxunyeni yeyona ibalulekileyo.Kwangaxeshanye, ukungunda kufuneka zigcinwe kwiimeko ezithile lobushushu, ubushushu ngundo kufuneka sizame ukufikelela utshintsho cyclical, iimfuno umthengi ubushushu ngundo kufuneka ibe phezulu, nto leyo enokunciphisa ngempumelelo ukunyibilika umkhondo, kunye neenxalenye zeplastiki off ubushushu ngundo. kufuneka ibephantsi.Ngaphandle koko ukuguqulwa kwemveliso kuya kuba kukhulu.Ngaphantsi kweemeko ezinjalo zokusebenza, i-mold iyakwazi ukuguqulwa ngokugqithisileyo kunye nokutshisa okutshisa kunye nokubandayo kokukhathala, ngokukodwa phantsi kwesenzo sokushisa kunye noxinzelelo.

Iplastiki kwinkqubo yokuzalisa i-mold cavity, i-mold forming parts by the high temperatures and high pressure melt melt scouring, flow friction, in the process of product demoulding, cavity and core and plastic parts in the work process is easy to produce friction, resulting kwinto yokugqoka ngundo.Ngelo xesha, ngenxa yokuvulwa rhoqo kunye nokuvalwa kwesikhunta, iinxalenye zesikhokelo sokubumba kunye neengxenye zokubumba zilungele ukugqoka kunye nokukrazula okubangela ukukhululeka.

Kwinkqubo yokubumba, ezinye iiplastiki ziya kubola phantsi kobushushu obuphezulu kunye noxinzelelo lokuvelisa iigesi ezitshabalalisayo, eziza kutshabalalisa ngokulula kunye nokonakalisa umphezulu wesikhunta, okwenza umonakalo ebusweni bombumba.

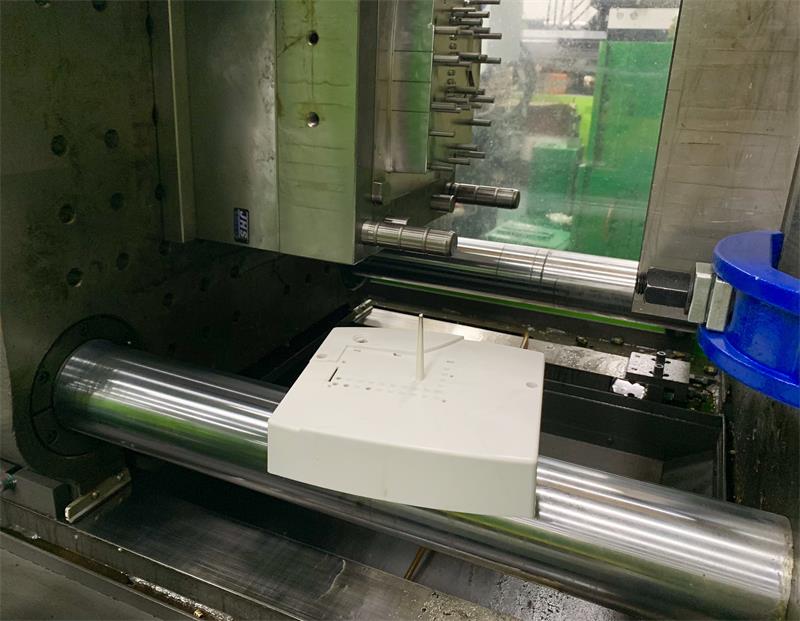

Xa imveliso yokubumba inaliti ifikelela kwinani elithile, umgangatho womphezulu wemveliso ngenxa yokuguga okugqithisileyo kokungunda awukwazi ukufikelela kwiimfuno, ukuphuphuma kwemveliso kunye nomphetho ophaphazelayo kubi kakhulu, kwaye umngxuma wokungunda kunye nombindi awunakulungiswa, ubomi bomngundo buphelelwa.Itotali yenani lamalungu eplastiki agqitywe phambi kokuba ukungunda kusilele kwaziwa ngokuba bubomi bomngundo.

Ixesha lokuposa: Jul-26-2022