Kule mihla, iimveliso zeplastiki zisebenza ngokupheleleyo ubomi bethu, nokuba yintoni na ekhaya okanye kwimizi-mveliso.Kodwa ngaba ngokwenene uyayazi indlela yokwenza ainxalenye yeplastiki?Qhubeka ufunda, eli nqaku liza kukuxelela.

Yintoni isitofu sokungunda

Isitofu sokubumba esidla ngokuchazwa njengepolima ye-thermoplastic ifudunyezwa ngaphezu kwendawo yokunyibilika, okukhokelela ekuguqulweni kwepolima eqinileyo ibe lulwelo olutyhidiweyo olune-viscosity ephantsi ngokufanelekileyo.Oku kunyibilika kunyanzeliswa ngoomatshini, oko kukuthi, ukutofwa, kwisingundo sokumila kwento yokugqibela efunekayo.Kwimveliso yoshishino, ukubunjwa kwenaliti yenye yezona nkqubo zibalulekileyo zokuvelisa izinto ezininzi ezivela kwi-thermoplastics.Abasebenzi badla ngokugalela imathiriyeli ekrwada yeplastiki eyomileyo (enje: ABDS, PP, TPU, PA66) kumgqomo womatshini wokubumba inaliti.Ke ngokweemfuno ezahlukeneyo zemveliso, amaqondo obushushu ahlukeneyo kunye nezantya zokutofa ziyilwe.Emva koko seta amaqondo obushushu ahlukeneyo kunye nesantya sokutofa ngokweemfuno ezahlukeneyo zemveliso.Emva kokupholisa kokugqibela ukwenza imveliso, ikhutshwa yipini ye-ejector.

Kutheni kufuneka isiko lokutofa ngundo

1.Imveliso yabucala kunye nokhuseleko

Ngexesha lenkqubo yokukhutshwa kwemveliso, ngokuqhelekileyo kwenzeka ukuba iimveliso eziye zenzelwe ixesha elide ziye zahlanjululwa ngaphambi kokuba zikhutshwe.Oku kuhlala kubangelwa kukuba abathengi basebenzisa iimold ezahlukeneyo esezenziwe ukuze bazidibanise ngexesha loyilo kunye nenkqubo yokubumba inaliti, kwaye abanayo isethi yabo yokubumba.Xa ulungelelanisa iseti yokubumba okukhethekileyo kwimveliso yakho, le ngxaki ayisayi kuphinda yenzeke, kuba siya kugcina iimbumba kumgaqo onokuthi uzisebenzise kuphela, kwaye wenze ukugcinwa rhoqo kuzo ukuze uzuze.Yisebenzise nanini na kamva.

2.Ukuntsonkotha

Xa ukhetha ukwenza ngokwezifiso iiseti zokubumba, iimveliso zakho aziyi kuphinda zithintelwe ngesakhiwo kunye nokubumba.Ngenxa yenqanaba eliphezulu lenkululeko yokwenza ngokwezifiso, unokuyila izakhiwo zemveliso ezintsonkothileyo ngokweemfuno zakho endaweni yokuzidibanisa kunye nokubumba okuninzi.Oku kuya kuphucula kakhulu ingqibelelo kunye nokunyaniseka kwemveliso.Ngoluhlu olubanzi lwangoku lwezicelo zesitofu sokubumba kunye nemizobo ye-3D, iimveliso oziyileyo zinokusuka kwikhaya ukuya kwiimveliso zoshishino.

3.Ixabiso eliphantsi

Ukusuka kwindawo yokujonga imveliso, ukwenza ngokwezifiso ukubumba kunokufuna ixabiso eliphezulu kunokusebenzisa i-mold esele yenziwe.Nangona kunjalo, ukusuka kwindawo yokujonga imveliso, ukubunjwa kwenaliti yinkqubo yokuvelisa ubuninzi kunye nokusetyenziswa kwexesha elide lokubumba okulungiselelwe ukuvelisa i-splicing.Iindleko ezilandelayo ziphezulu kakhulu, ngoko ke xa ukhetha i-mold customized, awuyi kudinga ukuhlawula nantoni na kwi-mold.

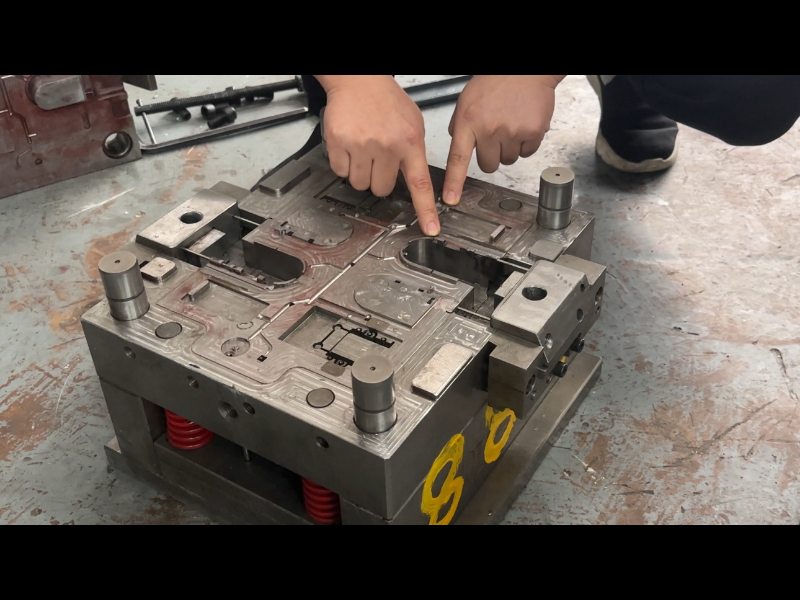

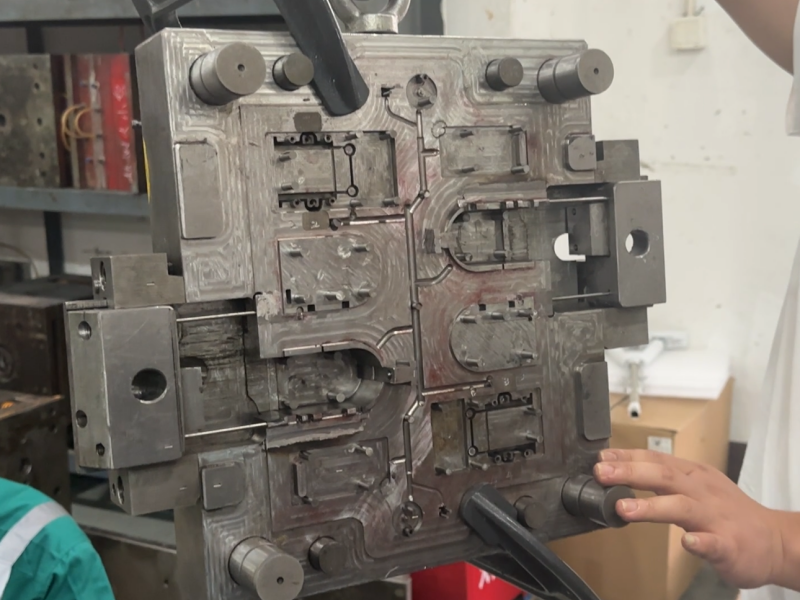

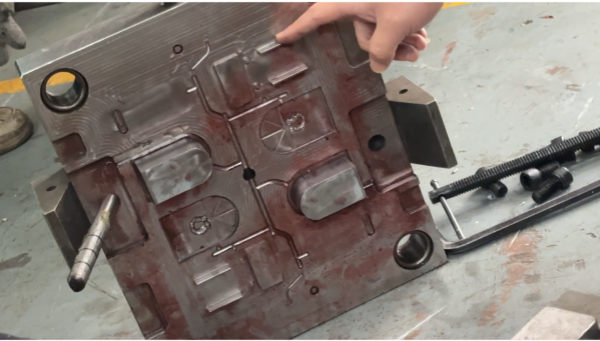

Indlela yokwenza isitofu sokungunda

Yila uMbumba kwiCAD

Uyilo lwesikhunta sesinye sezona nyathelo zibalulekileyo kwinkqubo.Eli linyathelo apho kufuneka wenze isigqibo malunga nokuba inxalenye iya kujongeka njani, iya kwenziwa njani kwaye zeziphi iimpawu eziya kuba nazo.Isitofu sokubumba yinkqubo entsonkothileyo, kwaye ukungunda yinxalenye enkulu yaloo nto.I-mold idinga ukukwazi ukumelana noxinzelelo oluphezulu kunye nokushisa kwenkqubo yokutofa, kunye nokusetyenziswa okuphindaphindiweyo.Yiyo loo nto kubalulekile ukufumana uyilo lokubumba ngokufanelekileyo okokuqala.Isoftware yeCAD inokukunceda wenze imodeli egqibeleleyo ye3D yenxalenye yakho onokuyisebenzisa ukwenza ukubumba.

3D Shicilela uMbumba

Inyathelo lokugqibela kukushicilela ukubumba usebenzisa iprinta ye-3D.Oku kuya kudala ukungunda kokugqibela, ubungakanani bokwenyani.Ukuba awuqinisekanga ukuba ungahamba njani ngale nto, zininzi izifundo ze-intanethi zokukunceda.Unokufumana kwakhona iinkonzo zoshicilelo ze-3D eziza kwenza umsebenzi kuwe.Ukuprinta umngundo linyathelo elibalulekileyo, njengoko liya kuqinisekisa ukuba imveliso egqityiweyo ikumgangatho ophezulu.

Ukuba ufuna ukwazi ngakumbi malunga noyilo lokubumba, unokufundaUyilo lokungunda kunye nokuveliswa kwezixhobo zePlastiki

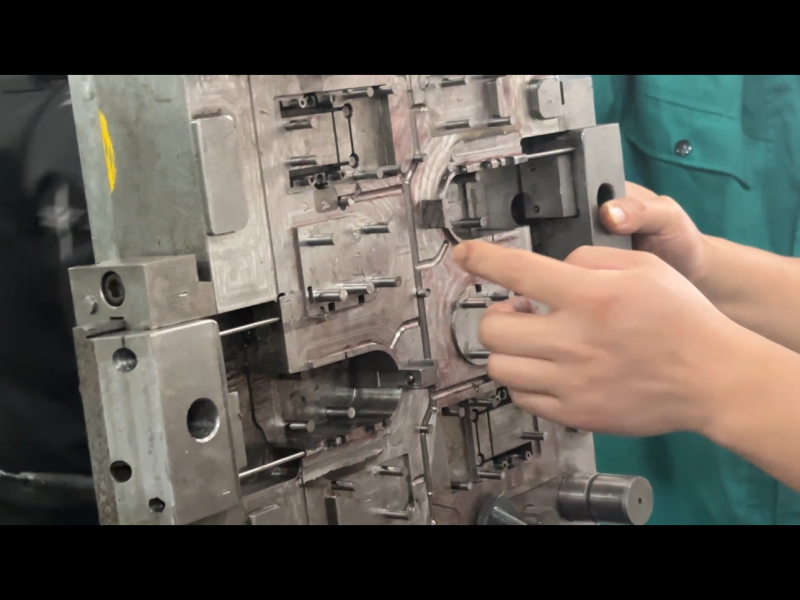

Ingxaki eqhelekileyo kwinkqubo yokwenza umngundo

1.isilayidi

Xa i-slider idibaniswe ngokudibanisa, ayikwazi ukudibanisa ngokupheleleyo i-mold.Xa isikhunta sivulwa kwaye sivaliwe, kulula ukubangela ukuba umphezulu othambekele uqhekeke.

2.umjelo wamanzi

Akukho mjelo wokuhamba kwamanzi ocwangcisiweyo xa uyila ukubumba, ojongene neengxaki zokupholisa imveliso.Ngaphezu koko, emva kokusetyenziswa kwexesha elide lokubumba, iqondo lokushisa lokubumba liya kuba liphezulu kwaye liphezulu, ekugqibeleni likhokelela ekuguqulweni kwemveliso okanye ukuphambuka kwendawo yomngxuma.

3.Impahla yokungunda

Ngethuba loyilo lwenkqubo yokubumba, ngenxa yokuba akukho zithuba zongezwa ukuvumela ioli ukuba ifake i-mold, i-coefficient ye-friction phakathi kweebhloko zentsimbi ngexesha lokugaya yayinkulu kakhulu, ibangela umonakalo kwi-mold.

I-4.Ulwabiwo lwe-slot yemveliso alunangqiqo

Kuba ukubunjwa kwenaliti kubandakanya ukutofa i-clinker yolwelo olunyibilikisiweyo olunobushushu obuphezulu kwi-groove yokubumba ukupholisa okokugqibela kwemveliso, umgodi wokungunda weemveliso ezinkulu kufuneka ube kufutshane nendawo yokungena yeglu ukunqanda ubushushu ukuba buphole ngenxa yomgama omde kwaye ukungakwazi ukutofa ngempumelelo kumngundo.Kodwa iimbumba zeemveliso ezincinci zifuna iplastiki encinci, ngoko ke i-grooves idla ngokuyilwa emaphethelweni esikhumbeni.

5.Isinyithi sokuhlala kwi-mold yokuqala

Intsimbi eshiyekileyo kubumba lokuqala ayithatyathelwa indawo ngokufaka.Ukuba umonakalo uyenzeka kamva, yonke inxalenye eseleyo yomzimba wokuqala kufuneka inqunyulwe ngocingo kwaye iphinde ifakwe.

Ukuba ungathanda ukwazi naluphi na ulwazi olunxulumeneyo malunga nenkqubo yokubumba inaliti okanye ukwenziwa komngundo, nceda uzive ukhululekileqhagamshelana neqela lethu lobuchwephesha.

Ixesha lokuposa: Apr-18-2024