Uhlalutyo lwe-CNC Machining Case of Aluminium Battery Shell

Iinkcukacha zeMveliso

Isicelo somthengi

1. Ukuvelisa inxalenye ngokwefayile ye-3D kwaye ulawule ukuchaneka ngaphakathi kwe-0.05M.

2. Ukuhlolwa kwe-CMM kubhekiselele kukunyamezela komzobo we-2D.

3. Qinisekisa ukuba indibano ilungile.

Uhlalutyo Lwethu

Emva kokufumana imizobo yoMthengi kunye nezicelo, iinjineli zethu zobuchwephesha zinohlalutyo olucokisekileyo kunye nokuqinisekisa ukuba sinokuvelisa le nxalenye ngokungqongqo kwaye silawule yonke imilinganiselo yokunyamezelana.Ukuqinisekisa ukuba indibano ilungile, sacela umxhasi ukuba anikeze umzobo weNdibano ukujonga ukuba akukho kuphazamiseka kwamanye amacandelo.

Qala ukusebenza

1. Ukucwangcisa

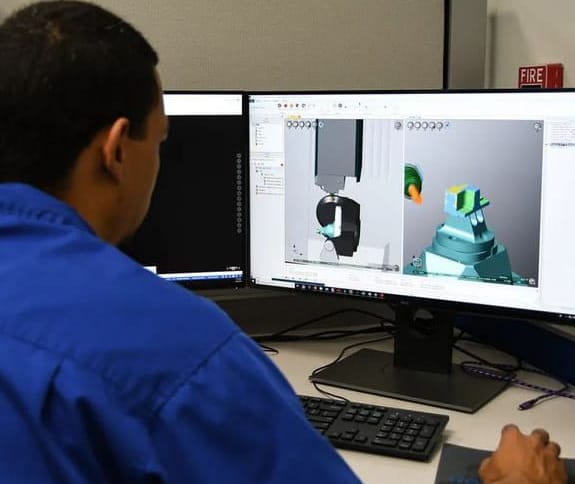

Umdwelisi wethu we-CNC usebenza ekuseteni iindlela zokusebenza zoomatshini.

2. CNC machining

Imveliso yenziwa ngoomatshini ngokucwangcisiweyo nangokutyibilikayo ngokweendlela zenkqubo esizibekayo.

3. Isandla silungisiwe

Umphezulu wendalo weemveliso emva kwe-CNC irhabaxa kwaye ineebhula ezininzi kunye neemela, umsebenzi wethu ngoku usebenzisa i-sandpaper ukucofa kunye nokupolisha umphezulu ukuze ube nenxalenye egudileyo ngaphandle kwemiphetho ebukhali.Inxalenye iya kuxutywa ukusuka kwi-coarse ukuya kwi-sandpaper ecocekileyo (i-400-1500) inqanaba lokugaya kude kube lula.

I-4.CMM (ukulungelelanisa umatshini wokulinganisa) Ukuhlolwa

I-QC yethu ilungisa umatshini we-CMM ukuba ube nokuhlolwa okuchanekileyo malunga nokuchaneka kwe-dimensional, ukubeka indawo, ukuchaneka kwejometri kunye nokuchaneka kwe-contour.

5.Ukuthumela ngenqanawa

Emva kokuba i-QC yethu inike ukukhanya okuluhlaza kule mveliso, siya kuyithumela ngephakheji eyomeleleyo yokukhusela imveliso.Ukuze yonke imveliso iya kuhanjiswa ikwimeko entle.